Comparing the new ANSI MH16.1-2021 standard to the previous 2012 standard.

The approach to calculating load capacities on racking systems has evolved over the years. The process has become more rigorous, leading to more precise values and, ultimately, safer racking arrangements. This is evident in the most recent revision of the ANSI MH16.1 standard, where the design requirements for steel storage racks have been updated.

These guidelines were created by the Rack Manufacturers Institute (RMI), an independent trade association incorporating the leading rack manufacturers in North America, to ensure that the racking standards remain current based on the latest research.

Notes on Using Rack Frame Tables

In the past, warehouse designers could refer to the manufacturer’s standardized frame tables to determine load capacities and use them to help organize racking systems accordingly [1]. A shortcoming of this method was that the values provided in the tables were governed by varying a single factor, apart from the inherent structural properties of the upright.

In 2021, the RMI/ANSI MH16.1 standard was revised to ensure that a total of nine design factors, unique to each warehouse, are considered in the load capacity calculations of a racking system. Here are how these factors affect the stability of a racking system and how Damotech incorporates them into our rack certification process.

ANSI MH16.1-2012 Standard

To fully understand the changes outlined in the latest revision of the ANSI standard, let us begin by examining how things were handled in the past.

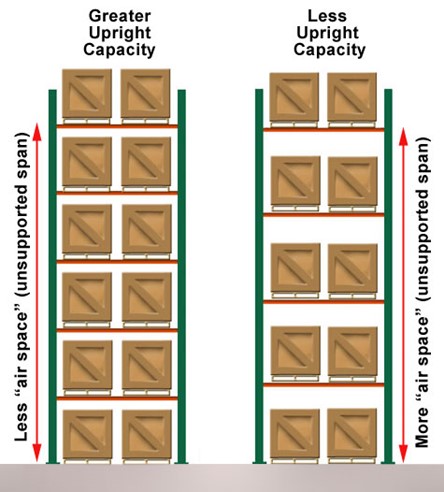

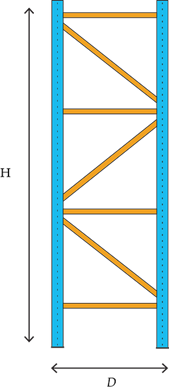

In earlier revisions of the MH16.1 standard, up until the 2021 revision, manufacturers could arrange the load capacities of their uprights into load capacity charts known as frame tables. These frame tables were a way for the manufacturers to simplify the rack selection/ arrangement process for their clients by providing load capacities of a given upright based primarily on the unbraced length of the column, the column’s unbraced length being the largest measurement between beam levels. In other words, it could be the height from the ground to the first beam level or the distance between two beam levels further up the upright, whichever is greater.

This method of calculating load capacities based on the unbraced length is also known as the effective length method.

Figure 1: Racking Systems with Different Unbraced Lengths

The client and designer would determine the required beam elevations. Once the beam elevations were selected, the largest unbraced length would be known. Uprights, or frames, could consequently be selected based on the total capacity desired by the client. With the capacity of the upright known, beams could then be chosen so long as their overall capacities are lower than the frame capacity.

Using the effective length method of calculating the capacity of uprights omits various important factors unique to individual warehouses that may affect the overall capacity of the racking system. Although some of these factors were already outlined in previous versions of the standard, including the 2012 standard, it was not until the 2021 revision that all factors were required to be considered when calculating the load capacity of a racking system.

This is not to say that the manufacturers did not consider these other factors in the overall design of the racking systems; rather, for the specific purpose of assigning load capacity, they simplified it to the fundamental frame tables.

ANSI MH16.1-2021 Standard

In the 2021 revision of the ANSI MH16.1 standard, new stability design requirements replaced the previous effective length method. These stricter requirements reference the “Design for Stability” sections of other ANSI standards for cold-formed and structural steel components, which, in turn, reference nine key design criteria. In the latest revision, these nine criteria, some of which had been alluded to in previous versions of the standard, are now further elaborated and mandatory to consider when determining the load capacity of a system. The nine criteria are as follows:

Rack average load to maximum load ratio

The maximum load is the highest load permitted to be stored in a specific location on the rack. The average load represents the expected load for each bay. For the load capacity analysis, the average load should not be less than 67% of the maximum load [2].

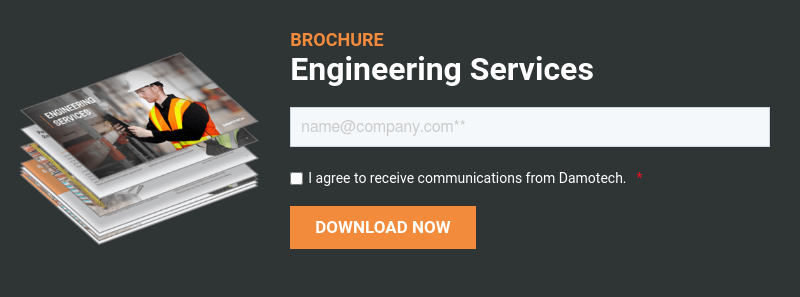

Rack beam-to-column connector stiffness and strength

The beam-to-column connection is very important for the overall strength and stiffness of a racking system. The more robust the connection between a beam and the supporting column, the stiffer the system will be and, in turn, the greater the load capacity.

Figure 2: Different Beam Attachment Types

Rack beam stiffness

The stiffness of a beam depends, in large part, on its size and shape. For example, one can intuitively gather that a six-inch-tall beam will be stiffer than a two-inch-tall beam of the same general shape/manufacturer. A long, thin beam can also reasonably be expected to carry less load than a short, thick beam.

Rack column stiffness

The shape and thickness of the steel used in industrial racking can influence its overall stiffness. Various methods of bracing individual columns to one another also play a role in an upright’s stiffness and rotational rigidity.

Rack base plate and anchorage details

It refers to the dimensions of the base plate and anchors used in a particular setup. Generally, the larger and thicker the baseplate is, the more stable it will be. Similarly, a larger, deeper anchor will provide added stability [3].

Warehouse site seismicity

Depending on where a warehouse is located, it may be at a greater risk of seismic activity and the forces associated with an earthquake. Warehouses in a zone of high seismic activity must consider these forces and use racks with the appropriate specifications. Given the likelihood of increased forces, one can expect lower load capacities for safety. To know more about how seismic forces can affect racks, please refer to our blog: Seismic Forces and Warehouse Pallet Racks.

Number of storage levels on racking

Generally speaking, a racking system with more storage levels is considered more stable than one with fewer storage levels. Assuming the same upright in both cases, if one set-up has more beams and one has less across the same height, then the one with more beam levels will have smaller gaps between beam levels. As seen in the older frame tables, this is associated with higher capacities. Thus, the beams’ arrangement should be considered when determining the load capacity of a racking system.

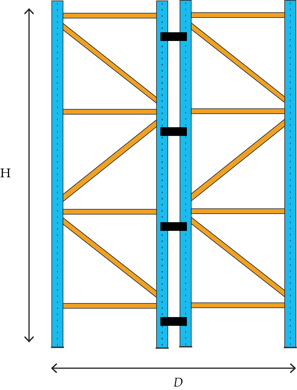

Rack frame aspect ratio

This factor is also known as the height-to-depth ratio. In most cases, the aspect ratio should not exceed six-to-one. Systems exceeding this ratio require special provisions to prevent overturning. The aspect ratio is calculated using the depth of the upright and the height of the highest beam level, as shown in the following figure. [2]. In the first diagram, the depth of the upright is the total depth. In the second case, row spacers (shown in black in the diagram) connect two uprights. Thus, the total depth is that of both uprights and the space in between.

Figure 3: Height to Depth Ratios

Warehouse or retail environment

Areas with higher foot traffic, such as warehouse-style retail stores, must consider the public's presence and have additional safety factors built into their systems. This can influence the load capacities assigned.

Damotech’s Load Capacity Calculation Methododology

At Damotech, we have always considered these nine factors during our load capacity calculations. To determine the load capacity of a racking system, our engineers take various measurements on-site, including, but not limited to, beam elevations, beam thicknesses, upright types, and steel gauges.

Relevant factors, such as seismicity, are also noted, and from there, a multitude of calculations are performed to provide load capacity results to our clients. We strive to provide accurate load capacities to help you maintain a safe warehouse environment.

Enhancing Warehouse Safety with the Revised RMI/ANSI MH16.1 Standard

The method of calculating the load capacities of racking systems according to the ANSI/RMI standard has changed significantly in recent years. More factors are now considered when calculating capacity values. They are evaluated on a case-by-case basis, meaning the capacities provided are now tailored to the specific conditions of your warehouse. This increase in accuracy ultimately contributes to making warehouses safer.

The frame tables used under the old standard are still useful but remain as reference documents. They can provide a quick estimate or even aid in the initial selection of components, but a complete calculation, including the nine new factors, would still need to be done.

Although racking systems certified using the 2012 standards may meet the criteria for the new 2021 standard, the RMI and Damotech recommend that older racking systems be recertified to ensure that the original load capacities are still valid [4].

If you want your racking assessed by our engineers, don’t hesitate to contact our engineering services. We would be happy to evaluate your racking systems.

Frequently Asked Questions - ANSI MH16.1

What is the purpose of the ANSI MH16.1 standard for steel storage racks?

How does the 2021 revision of ANSI MH16.1 differ from the 2012 standard?

Why were the old frame tables replaced?

What are the nine design factors that must be evaluated under ANSI MH16.1-2021?

Each racking system’s load capacity must account for:

1. Rack average-to-maximum load ratio

2. Beam-to-column connector stiffness and strength

3. Beam stiffness

4. Column stiffness

5. Base-plate and anchorage details

6. Warehouse site seismicity

7. Number of storage levels

8. Rack frame aspect ratio (height-to-depth)

9. Warehouse or retail environment

Together, these factors create a more realistic representation of how the rack will perform in service.

How do these new factors improve warehouse safety?

What does “effective length method” mean, and why is it no longer sufficient?

Do older racks designed under ANSI MH16.1-2012 still comply with 2021 requirements?

How does Damotech incorporate the 2021 standard in its load capacity certification?

What are the benefits of recertifying racking systems under ANSI MH16.1?

2. Confirms accurate load ratings for all beam levels

3. Reduces risk of overloading or structural failure

4. Improves audit readiness and insurance compliance

5. Extends the life of your racking infrastructure

Where can warehouse managers learn more about ANSI MH16.1 and rack capacity?

1. Free webinars, including “Can your warehouse handle the weight?”

2. The Rack Load Capacity Guide

3. Engineering services for load certification, rack inspections, and safety training

These help warehouses stay aligned with ANSI MH16.1 and maintain the highest standards of rack safety.

Learn more or book an engineering assessment here: https://www.damotech.com/talk-to-an-expert-lp

References

[1] Unarco, “RMI SPECIFICATION REGARDING FRAME TABLES,” April 2022. [Online]. Available: https://www.unarcorack.com/pallet-rack-capacities/rmi-specification-regarding-frame-tables/.

[2] Rack Manufacturers Institute, “Design, Testing, and Utilization of Industrial Steel Storage Racks,” ANSI MH16.1-2021, 2021.

[3] CSST, “Safety of Pallet Racks; Construction, Purchase, Installation and Use,” Prevention Guide, 2005.

[4] Rack Manufacturers Institute, “Load Capacity Requirements In The New RMI Storage Rack Standard ANSI MH16.1-2021,” 30 June 2022. [Online]. Available: http://www.rmiracksafety.org/2022/06/30/load-capacity-requirements-in-the-new-rmi-storage-rack-standard-ansi-mh16-1-2021/.

[5] Rack Manufacturers Institute, “Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks,” ANSI MH16.1: 2012, 2012.