What is the clearance for pallet racking? Here’s what you need to know about warehouse racking safety guidelines.

Our daily lives have no strict rules about what is too close for comfort. Some people go through life blissfully unaware that they make people uncomfortable by intruding on their space.

Pallet racking clearance, however, has more specific regulations and guidelines that dictate the minimum distance between pallet racking systems and the building’s structure to comply with safety rules like OSHA regulations.

Connecting warehouse racks to building components

Pallet racks are self-sufficient and freestanding structures. Building components (e.g., walls, columns, beams, etc.) are not typically designed to support additional loads from neighboring structures, which is why storage rack clearance is so important.

Securing pallet racks to building components allows forces to transfer between them, which could have unintended consequences. Unless a structural engineer specifically designed the structures to interact, connecting pallet racks to building components is not recommended and could prove dangerous.

Figure 1. Example of a pallet rack connected to a building structure (not recommended by engineers).

How far does pallet racking need to be from a building structure?

Ensuring warehouse racks are not connected to a building component is insufficient. To prevent contact between building components and pallet racks through vibrations (caused by activities in the warehouse, impact, or a seismic event), a specific storage rack clearance from the building's structure should be respected.

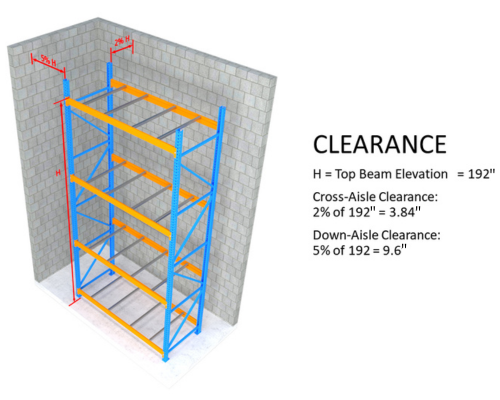

Unless you have previously determined by seismic analysis the amplitude of movement of the racks, current standards require a minimum warehouse racking clearance equal to:

- 5% of the racking height with the building in the down-aisle direction

- 2% of the racking height with the building in the cross-aisle direction

The figure on the right illustrates an example: if the top beam elevation is 192" high, the required clearances are calculated as percentages of that height. Cross-aisle clearance is 2% of 192", which equals 3.84", and down-aisle clearance is 5%, or 9.6".

How much space do you need between pallet racking?

Multiplying the height of your pallet rack times 0.05 for down-aisle or 0.02 for cross-aisle directions will allow you to determine your storage rack clearances. For example, if your pallet rack is 240 inches tall (20 feet), the required clearance would be 12 inches (5% of 240) in the down-aisle direction and 4.8 inches (2% of 240) in the cross-aisle direction.

If you are certain that the topmost beam elevation will not be modified over time, the topmost beam height can be used instead of the rack’s total height to determine the required distance between pallet racking.

Why Clearance Distances Matter

In the event of an impact or seismic activity, a pallet rack could damage a building component if it’s too close, compromising its load-carrying capacity. The rack could also damage non-load-bearing components such as non-supporting walls, plumbing or electrical infrastructures, sprinkler systems, and other warehouse equipment. The figure below shows an example of an upright that does not respect the recommended clearance distance between pallet racking and a building column.

Figure 3. Rack upright too close to a structural building column.

Other recommended clearance guidelines related to warehouse racks and pallets

Aside from storage rack clearance and the distance with the building components, there are other clearances to keep in mind in your warehouse. Storing pallets within the recommended clearances will reduce damage to pallet rack components and ensure safe and efficient operation.

Minimum distances are recommended for proper handling and protection of pallet racks. Table 1 below lists the required general clearances for single-deep/double-deep pallet racks.

Table 1: Recommended storage rack clearances for single-deep and double-deep pallet racks

| # | Clearance Guideline | Recommended clearance space |

|---|---|---|

| 1 | Between two loads and between one load and the upright frame | At least 3 in. |

| 2 | Between the load and the overhead beam | At least 3 in. (and more for safe handling at top levels) |

| 3 | Pallet overhang | Between 2 and 4 in. over the front and back beams |

| 4 | Between two loads in back-to-back cells | At least 4 in. |

| 5 | Service aisle |

|

| 6 | Main aisle | According to the lift truck manufacturer’s recommendations |

| 7 | Between load and an automatic sprinkler system | At least 18 in. |

| 8 | Walkways |

|

How much space do you need between pallets?

As shown in the table above, pallets should have a minimum clearance of 3 inches between them to avoid damage or unintended impacts with rack components. Lift truck drivers should pay close attention and ensure adequate space on both pallet sides when placing pallets.

What is the minimum clearance between pallets and a racking structure?

There should be at least 3 inches of clearance between each pallet and the rack column to prevent damage or accidental contact with rack components. Figure 4 below shows a pallet stored directly against a column. Failure to observe the recommended storage rack clearance can damage the pallet rack components.

Figure 4. Improper storage clearance between pallet and rack column.

Storage rack clearance: Warehouse safety guidelines to remember

Pallet racks are efficient structures for storing large quantities of heavy merchandise, but standards must be followed to ensure they are used safely and remain free of damage. Following the minimum distance between racking and respecting clearance from building components is important.

Stay on top of OSHA safety standards with regular rack inspections

Regularly inspecting your warehouse racks is one of the most effective ways to stay compliant with OSHA standards and maintain proper clearances for a safe working environment.

Not sure if your pallet rack clearances are up to code? Our team of expert engineers is here to help—whether you need a one-time consultation, ongoing safety management, or answers to your specific warehouse challenges. Explore our full range of services to see how we can support your operations.

You can also streamline your inspection process with tools like the Damotech Platform. This powerful solution lets you view and track rack inspections in real time using an intuitive dashboard that maps your warehouse layout. It’s a smart, efficient way to stay on top of safety anytime, from anywhere.

Curious to see it in action? Watch the demo and discover how you can take control of your rack inspection management.

FAQ for Pallet‑Rack Clearances & Safe Distances

What clearance is required between pallet racks and the building (walls, columns, mezzanine posts, etc.)?

Should I connect pallet racks to building columns or walls?

How much space should I leave between adjacent pallets on the same beam level?

What pallet overhang is recommended on the front and back beams?

How much space should there be between two pallets or between a pallet and the upright frame?

What is the required clearance between the top of a load and the beam above it?

How much clearance is needed between loads stored back-to-back?

What are the minimum service-aisle requirements for forklifts?

One-way traffic: The aisle should be at least the truck’s length (with its load) plus 6" on each side, or meet the lift truck manufacturer’s minimum recommendation.

Two-way traffic: Follow the lift-truck manufacturer’s recommended width to ensure safe passing and turning.

How wide should the main aisles be in a warehouse?

How much vertical space must be left between the top of stored goods and sprinkler heads?

What are the minimum walkway dimensions for employees?