Because of pallet rack safety regulations in North America and growing demand for greater warehouse safety, your racks must have known load capacities. Any adjustments made to the configuration of a rack, such as a change in beam or displacement in height, must be reviewed by a racking specialist before it is put back to use. Damotech offers load capacity calculation and certification services by qualified engineers with expertise in industrial pallet racking systems.

Knowing and displaying your pallet rack load capacities is critical to the safe operation of your warehouse. However, many facilities don’t have their original rack design and configuration drawings (LARCS). Hence, no accurate or verified beam weight capacity ratings are displayed for forklift drivers. When a beam's height is adjusted, a beam is added or removed, or a beam is replaced with another beam with different specifications, the weight capacity of each beam pair in the system must be recalculated. Our weight capacity calculation services determine any rack system's maximum capacity through sophisticated modeling and calculations. Damotech will produce all the required labels or plaques to display weight capacities for your racking systems properly.

Damotech Engineering Services (DES) will first collect the necessary measurements of your racking systems. Then, we will calculate the load capacity of each upright and beam pair. Finally, we will issue a rack load capacity report and provide beam capacity labels or plaques identifying the maximum load capacities of each palette position. The process is entirely non-disruptive to your warehouse operations.

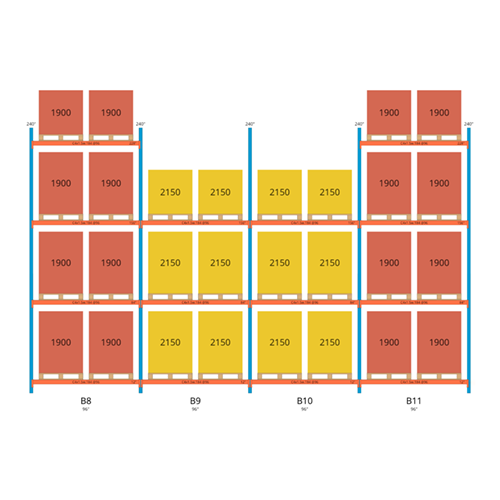

Our engineers will produce a pallet racking weight capacity report containing drawings and the load capacity of each rack position and beam level.

The report includes:

Damotech's in-house engineers are among the most knowledgeable in the industry. They offer expert services on warehouse racking systems and their safety. Learn more about our rack safety audits, load capacity calculations, and warehouse safety trainings.

0

Fortune 500 Clients

0

MSq. Ft. Inspected

0

1MHours of Downtime Saved

0

%Warranty Replacements

250

Fortune 500 Clients

500

MSq. Ft. Inspected

Hours of Downtime Saved

Warranty Replacements

Warehouse Employee Safety

Having racking beam capacities calculated and always displayed near your racking systems ensures that forklift drivers have the right information to make safe decisions.

Professional Engineers

Professional engineers perform and stamp all our rack weight calculations and racking drawings.

Quick Report Delivery

Rack load calculation reports are typically delivered less than a month after receiving the purchase order.

Racking Seismic Expertise

The racking load weight calculations produced by Damotech engineers take into account your warehouse location and potential seismic effects on pallet racks.

North American Network

No matter where you are in the United States or Canada, no matter the size of your warehouses, Damotech can provide you with pallet rack weight capacities for OSHA compliance.

Most Trusted Rack Engineers

Most of the top-performing large (and small) corporations trust Damotech's engineering professionals with the safety of their rack systems.

While storage rack regulations may not explicitly mandate the inclusion of capacity ratings, OSHA may invoke the General Duty Clause, especially in cases of rack collapse due to overloading. Even in the absence of a collapse, racks exhibiting signs of sagging or other indications of overloading pose potential safety hazards.

OSHA, in justifying a General Duty Clause citation, may reference recommendations from the rack manufacturer or adhere to ANSI/MH 16.1 standards. These references empower OSHA to demonstrate that the installation of a load rating sign could help mitigate recognized hazards and enhance overall safety in the workplace.

Learn more about ANSI/MH 16.1, Design, Testing, And Utilization Of Industrial Steel Storage Racks.

Yes, it's possible if the chart is signed by an engineer for your specific site. General load capacity charts published by the OEM cannot take into account seismic effects. Therefore, a chart must be calculated for your specific rack configurations and location.

No, capacity labels are not necessary on all beam levels. The American and Canadian building codes refer to the rack design standards that indicate that individual beam load capacity weights must be displayed on rack systems. Neither code imposes a method for communicating load capacities, but labels on each bay or load capacity plaques at the end of aisles are most common.

There are several ways to communicate the load capacity of a racking system. We suggest placing labels on the first beam elevation, ideally near eye level, since it allows for varying weight load capacity throughout a rack system. When the racks are uniformly designed, rack load capacity plaques can be displayed at the end of aisles and in tunnels.

Did you know that a change in a beam elevation will most likely affect the load capacity of other beams (even in neighboring bays)? Therefore, in most jurisdictions in North America, any change to a rack must be reviewed by a racking specialist before being put into service again. That is because some seemingly minor changes may negatively impact the racking system's load-bearing performance. Adding, removing, or replacing a beam with different specs may also affect the load-bearing capacity of your entire racking system. Replacing a beam with an identical one (same size, specs, and location) will not affect the racking systems' weight capacity. Don't forget to re-install the locking safety pins.

There are no regions that are not seismic. It’s just that some regions experience so very small tremors that other load effects control the design of the racking system. If your warehouse is located in a high seismic zone like the east and west coasts of North America (U.S. and Canada) or near Memphis, you have more reasons to maintain the safety (and structural integrity) of your racks as the horizontal movement during a seismic event will generate substantially more loads on your rack systems than in other regions.

LARC stands for Load Application and Rack Configuration. These are stamped engineering drawings (often referred to as CAD drawings) of the rack systems in your warehouse. Typically, the OEM (original equipment manufacturer) provides these when installing the new racking systems. If racks are reconfigured after the initial installation, new LARCs with weight capacities must be produced by an engineer. Learn more about LARCs in this article.

A PSR stands for Pre-Start Health and Safety Review. In some jurisdictions in North America, such as Ontario, any modification to a pallet rack system must be reviewed by a knowledgeable rack expert before it is put back into use. Learn more about PSR on this page.

Be careful using those, and read the small characters at the bottom of the chart. They indicate that the chart does not take into account all possible loads like seismic forces and that all components must be compatible and come from the same manufacturer.

Also, to respect the building and OSHA codes, a professional engineer must certify the racks for load capacity.

It’s not that we want to skirt around the subject of pricing. We like to know what things cost, too.

We tailor our weight capacity calculation services to our customers' needs anywhere in the United States or Canada. Consequently, our pricing factors geographic location, warehouse size, racking type and environment (freezers, cold storage, exterior, ...), to offer a detailed quote and avoid any surprises.

To get more information on pricing; request a free quote or call 1 (877) 990-3266 and let us demonstrate the value of our engineering services.

Yes. Damotech always provides engineer-stamped load capacities prepared and sealed by a licensed Professional Engineer. An engineer-stamped report formally certifies that your specific rack configuration has been structurally analyzed and complies with applicable building codes and industry standards.

While the engineer-stamped report includes the certified allowable load capacities and engineering conclusions, it does not include the full mathematical calculation derivations or proprietary engineering models (stamped calcs). Our engineer-stamped documents provide the validated results and compliance confirmation necessary for regulatory, insurance, and operational purposes.

Engineer-stamped capacities are typically required for rack modifications, height changes, seismic compliance, insurance documentation, or when requested by local authorities.

Introducing the Rack Safety Flywheel by Damotech! With over 35 years of industry experience, we've condensed our wealth of knowledge into this powerful tool designed to keep your warehouse operations running smoothly and securely. Our Flywheel breaks down safety principles into easy-to-follow courses of action, giving you the peace of mind of a comprehensive safety program.

Discover the Rack Safety Flywheel