In recent decades, the global economy has witnessed significant changes, accompanied by a surge in consumer demand. This transformation has left an indelible mark on the warehousing industry, prompting it to adapt and expand. The growing demand for products has led employers to increase their production capacities and, consequently, their storage facilities. This surge in growth has resulted in the construction of countless warehouses and distribution centers (DCs) across the United States and globally. Simultaneously, it has driven a substantial increase in warehouse employment.

Warehousing's Growing Workforce: Challenges and Safety Imperatives

Projections paint a vivid picture of the future, indicating that this upward trajectory in warehousing will continue. While this explosive growth promises economic opportunities, it also underscores the urgent need for employers to prioritize the safety of their employees. Navigating the complex terrain of compliance with Occupational Safety and Health Administration (OSHA) guidelines becomes even more critical, given the challenges of managing an ever-expanding workforce.

Surprising U.S. Warehouse Industry Safety and Accident Statistics

In this article, we delve into the surprising safety statistics of the warehouse industry. Through these statistics, we aim to shed light on the factors shaping the present and future of the warehousing industry in the United States. Discover this dynamic sector's trends, challenges, and safety imperatives.

Statistic #1. The Number of Warehouse Employees Has Doubled in the Last Ten Years

|

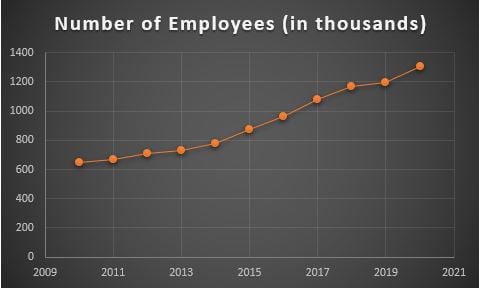

| Figure 1: Warehouse employee growth over the years. |

Rising product demand has prompted employers to expand their production and storage capacities. This growth has led to the construction of more warehouses and distribution centers (DCs), as well as increased warehouse employment. According to the U.S. Bureau of Labor Statistics, the number of employees has doubled from 645,200 in 2010 to 1,304,900 in 2020 (Figure 1). Projections indicate that this trend will continue, with nearly 2 million employees expected by 2030. With such growth, the responsibility of employers to ensure employee safety and comply with OSHA guidelines becomes even more critical and challenging, given the larger workforce to manage.

Statistic #2. There Are Less Than 30 Fatalities Per Year in U.S. Warehouses

|

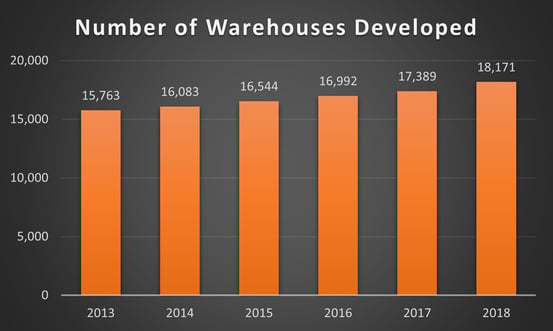

| Figure 2: Annual increase in warehouse development. |

|

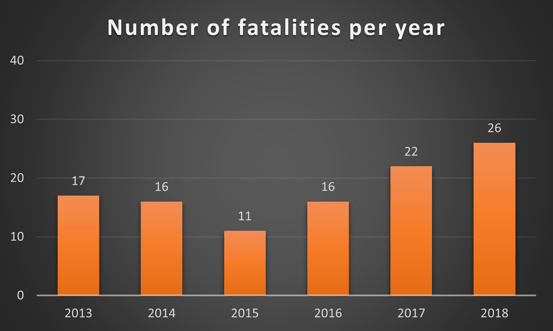

| Figure 3: Number of recorded fatalities in the warehouse industry. |

Based on data from the U.S. Bureau of Labor Statistics in 2019, the average rate of recorded injuries in the warehousing industry was 4.8 per 100 full-time workers, slightly lower than the previous year's rate of 5.1. These numbers encompass cases resulting in days away from work and job transfers. While the rate of injuries decreased, it still accounted for nearly 8% of the 2.8 million non-fatal workplace injuries and illnesses reported by private industry employers. Encouragingly, despite the annual growth in warehouse development (as shown in Figure 2, with warehouses increasing from 16,544 in 2015 to 18,171 in 2018, an average yearly increase of 4%), the number of reported fatalities remains relatively stable. Figure 3 reveals that annual fatalities have consistently stayed below 30 since 2013, reaching a low of 11 in 2015.

Statistic #3. Forklifts are responsible for 90% of Pallet Rack Accidents

Pallet rack failures can result from various factors, including system overload, inadequate maintenance, and collisions with forklifts. In most cases, it stems from a combination of all the above.

Forklifts are one of the most essential tools for warehousing at our disposal. They help maneuver goods quickly and efficiently, but must be used properly. The chances of racking system damage increase exponentially when a forklift is involved. Read this article to learn about the five most common ways forklifts damage racks. According to one report, 90% of rack failures can be attributed to forklift impacts. The dynamic movements and weight of forklifts make them prone to collisions with pallet racks. This risk can be significantly reduced by properly training forklift operators, wider aisle spaces, and installing protection devices such as rack guards.

Statistic #4. Forklift Truck Overturning is the Primary Cause of Fatal Incidents

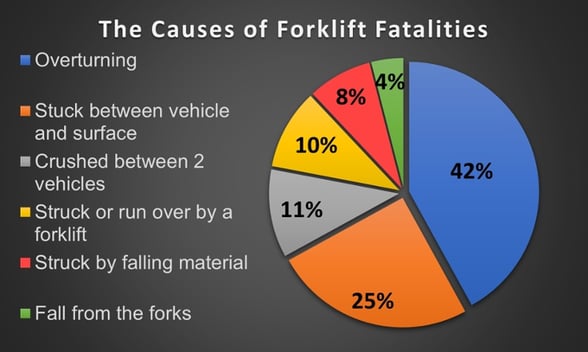

While one might assume that being struck head-on by a forklift is the most common accident, OSHA data reveals that over 40% of fatalities result from forklift overturning or tipping. In comparison, only 10% are caused by direct collisions. Figure 4 illustrates the distribution of forklift fatalities by type.

|

| Figure 4: Pie chart demonstrating the causes of forklift fatalities. |

Preventing such incidents requires comprehensive employee training and strict adherence to warehouse guidelines, including:

- Making employees familiar with different types of forklifts and their respective weight capacities.

- Emphasizing the importance of aisle width and clearance.

- Promoting the maintenance of safe speeds throughout the warehouse.

The Occupational Safety & Health Administration (OSHA) estimates that implementing these measures could prevent approximately 70% of forklift accidents in the United States.

Statistic #5. Injuries Cost More than $84 Million Per Week in the U.S.

When considering the financial impact of workplace incidents, it is essential to recognize that costs extend beyond insurance and medical bills. In 2018, the National Safety Council reported that the average cost per medically consulted injury was $41,000, while the cost per fatality amounted to $1,190,000. These costs encompass both direct and indirect expenses, such as medical treatments, equipment damage, lost production time, and training replacement staff. Non-fatal injuries in the transportation and warehousing industry alone cost approximately $84.04 million per week in 2018, averaging $240,000 annually for each of the 18,171 warehouses. Furthermore, non-compliance with safety guidelines can lead to fines from OSHA, ranging from $7,000 for minor infractions to $70,000 for repeat offenses. Investing a fraction of these amounts in rack protection devices and comprehensive training can significantly improve workplace safety and reduce injuries.

Reducing Accidents and Improving Warehouse Safety Statistics in America

Since the implementation of safety guidelines by OSHA in 1970, occupational deaths have declined by 62%, and workplace-related injuries have decreased by 42%. These remarkable improvements demonstrate the positive impact of adhering to safety protocols in reducing injury and fatality rates. However, there is still much work to be done. Achieving the goal of zero fatalities is possible through meticulous planning, practical safety training, the use of protective devices, and regular racking inspections. With these measures in place, a safer work environment can be attained, bringing us closer to the day when warehouse fatalities become a thing of the past.

Frequently Asked Questions: 5 Surprising Warehouse Accident and Injury Statistics

Why are warehouse accident statistics vital for managers to track?

How has warehouse employment growth affected worker safety?

Are warehouse fatalities common in the United States?

What role do forklifts play in warehouse accidents?

Forklifts are essential, but also a leading cause of warehouse accidents. They are involved in many pallet rack impacts and nearly 40% of fatal warehouse incidents. The leading cause of forklift-related deaths is overturning, not collision. To reduce forklift hazards:

- Maintain proper aisle clearances

- Train and certify operators according to OSHA standard 29 CFR 1910.178

- Install rack protection systems in high-traffic zones

OSHA estimates these steps could prevent up to 70% of forklift accidents nationwide.

How much do workplace injuries cost the warehousing industry?

What are the most effective ways to prevent warehouse accidents?

The most effective prevention strategies include:

- Comprehensive safety training for forklift and equipment operators

- Routine rack inspections to identify damage or unsafe configurations

- Adherence to OSHA and ANSI standards for load capacities and aisle clearances

- Use of engineered rack protection to reduce impact damage

- Data-driven safety programs that track and analyze near-miss incidents

Warehouses that implement these measures experience significantly lower injury rates and insurance costs.

What progress has been made in warehouse safety since OSHA’s creation?

How can warehouse managers use these statistics to improve safety performance?

What resources are available to help warehouses reduce accidents?

Damotech offers several free tools and resources, including:

- The Rack Compliance eBook to understand OSHA requirements and inspection readiness

- A Rack Inspection Checklist to document rack damage and maintenance

- A Free Rack Damage Assessment, where our experts go to your facility and assess the damage, and offer expert advice on the best way to fix the damage

These resources empower warehouse professionals to take practical, compliant steps toward a safer facility.

How can Damotech help warehouses improve their safety statistics?

References:

- https://www.bea.gov/data/consumer-spending/main

- https://data.bls.gov/timeseries/CES4349300001

- https://www.bls.gov/iag/tgs/iag493.htm

- https://www.bls.gov/news.release/pdf/osh.pdf

- https://www.statista.com/statistics/873492/total-number-of-warehouses-united-states/

- http://www.cleanlink.com/sm/graphics/15/09/sm0915.pdf

- https://www.safetyinnumbers.ca/wp-content/uploads/2018/04/Forklift-Accident-Statistics-2018.pdf

- https://www.osha.gov/

- https://injuryfacts.nsc.org/work/costs/work-injury-costs/