When considering causes of damage and issues with industrial racking, forklifts immediately spring to mind. Because of their size, speed, and complex maneuverability, forklifts are prone to hit racking elements. These collisions can, in turn, create shearing, twisting, bending, and deformations on pallet racks. However, rack damage is not limited to impacts from forklifts.

This blog post will show how corrosion, overloading, and in-house modifications can lead to pallet rack issues. We will additionally cover how improper storage, poor installation, and encumbrance can also cause damage over time.

1. Corrosion

Rust eats away at the steel that makes up the racking system and thins it out. If untreated, it is a problem that worsens over time, eventually leading to some cases where replacement is needed. In climates with elevated moisture levels or in exterior environments, racking is at risk of developing rust.

The types of products stored on the racks can also play a role in accelerating the corrosion process. For example, rust can be expected to form if certain fertilizers or chemical salts leak from their packaging and come into contact with the racking.

Figure 1: Salt spilled onto pallet racking Figure 2: Salt accelerating rust on racks

Figure 3: Fertilizer accelerating rust Figure 4: White runoff of fertilizer after rain

It is possible to mitigate the risk of corrosion. The best way is to select racking components with the appropriate type of surface treatment for the rack’s environment. Galvanized beams and uprights can resist the elements much longer than components that were simply painted. As for the case of storing chemicals, care should be taken to ensure these stored goods are well contained.

Although knowing how to prioritize rust issues can be tricky, online resources and articles can help you analyze the state of rust on your pallet racks.

2. Overloading

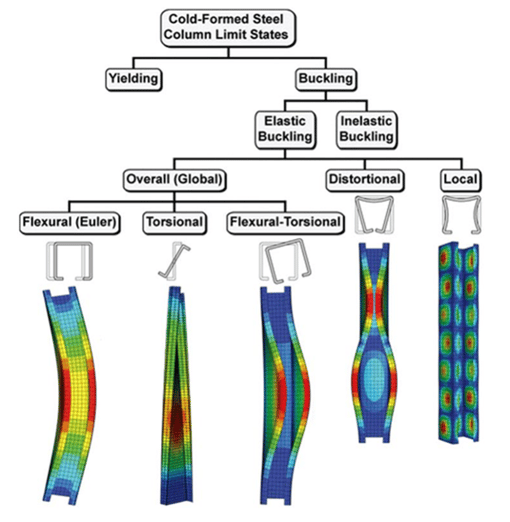

If an upright is overloaded, it is prone to buckling, which can lead to sudden collapse. Buckling can take many forms, as shown in the figure to the right. Depending on the severity, there is a chance the column will return elastically to its original state once the excess weight is removed.

Otherwise, there may be a permanent deformation that will act as a stress concentration. That is to say, the affected portion of the column would become a weak point, resulting in a lowered load capacity.

If beams are overloaded, they will bend downwards in a concave fashion regarding the load. If the bending is severe enough (past allowable limits), the beam deflection will be permanent and remain bent even after the load is removed. A beam that has been permanently weakened cannot be relied upon to carry its initial load capacity.

Figure 5: Different types of buckling

How can this type of damage be mitigated? By using appropriate beam sizes according to the weight of the stored goods and by respecting the stamped engineered drawings for the rack system.

Figure 6: Beam deflections

2.1. Configuration change

Changing the configuration of a racking system can drastically alter its stability and load carrying capacity. For example, removing the first beam level will augment the length of the laterally unsupported portion of the column, which will diminish its load capacity. Even if the rack now has fewer pallets than it used to have, it may not have enough capacity to support what’s left.

This situation is common when high-level beams are maintained, but low-level beams are removed. This creates a taller region along the upright’s height that is unbraced on the horizontal axis. Thus, there is more free vertical length upon which the upright can bend.

If a beam configuration needs to be changed, the manufacturer or a certified engineer must approve the changes, and new load capacity documents are required [2].

2.2. Unequal beams

Occasionally, beams of different sizes are paired together at the same level. If the smaller of the two is insufficiently large to support the loads, it will begin bending. Occasionally, the smaller beam is located behind the larger one, which makes it misleading for staff when stocking merchandise.

Identical front and back beams should be used at the same beam levels to avoid this type of issue.

3. Improper storage

Improper storage of pallets or material within a pallet rack is an issue that increases the likelihood of incidents or damage occurring. The following situations should be avoided as much as possible.

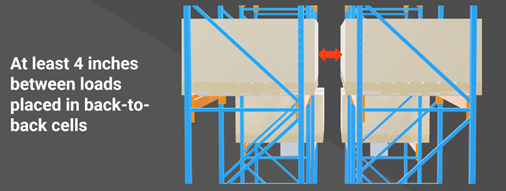

3.1 Pallet overhang

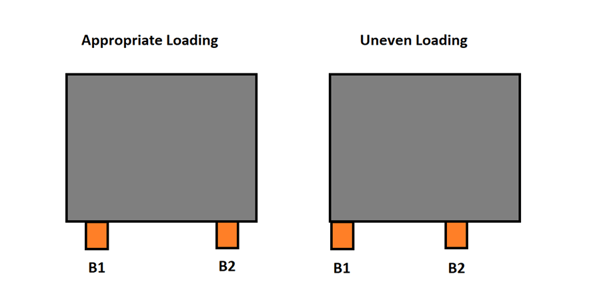

Pallets are sometimes placed on the racks unevenly, leading to one beam bearing more load than the other. If the pallet load is close to the maximum amount permissible for that cell, the beam bearing the brunt of the weight may begin to deflect excessively. As shown in the figure below, the second beam (B2) would support a more significant part of the load than the first beam in the case of uneven loading.

Figure 7: Excessive pallet overhang

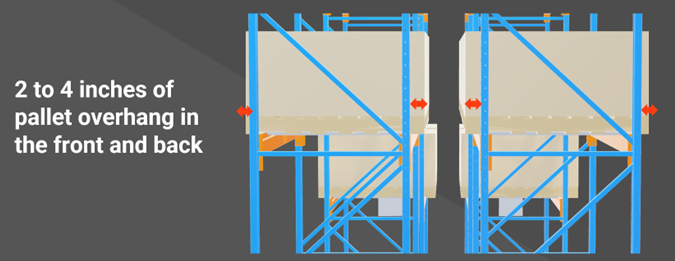

To keep your pallet racks safer, avoid pallet overhang in your systems by more than the maximum recommended amount of 4 inches on both the front and back beams [3].

Figure 8: Pallet overhang allowance

3.2. Upright bracing

The horizontal and diagonal members of an upright bracing are designed specifically to counteract cross-aisle displacement. Products are sometimes placed leaning in a down-aisle direction against the bracing of a rack. The bracing isn’t designed for this purpose, and if the loads are too heavy, it may become bent, or its welds may crack over time. The figure below shows a tall and heavy load leaning against one of the horizontal braces of an upright.

Figure 9: Load leaning on bracing

Another example of this type of issue is shown below: a system onto which a flat top level was created by placing a large sheet of corrugated metal across two horizontal braces. While it may seem ideal for storing loose or similarly long products, the above concerns still apply.

Figure 10: Material supported by bracing

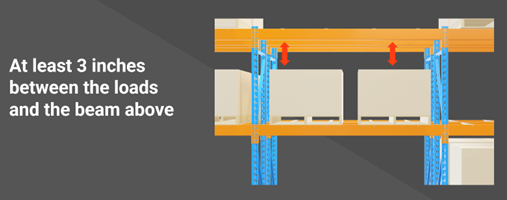

3.3. Clearance

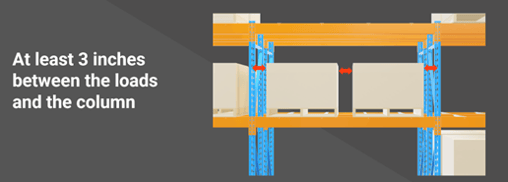

If the overhead beam is very close to the material stored on the pallet beneath it, then accessing that pallet can become more precarious. Lifting the pallet could uplift the beam above it as the stored material pushes against it. This could lead to detached or unhinged beams unless they are properly secured (with safety pins, for example). Leaving adequate flue space around pallets is also important in the case of a fire. It gives sprinklers or hoses easy entry points for the water to flow into the confined areas of a rack. It is recommended to leave a minimum of 3 inches above and to the sides of each pallet [3].

Figure 11: Recommended clearances

3.4. Sprinkler clearance

Automatic sprinkler systems are often installed close to racking systems to put out fires in the confined spaces of a rack. If they are too close to the stored material, they may get damaged as pallets are loaded and unloaded. The resulting water leaks could, in turn, damage the stored merchandise and the warehouse. To mitigate the risk of this issue, all material should be stored with the recommended clearance associated with the type of sprinkler head used [2].

3.5. Storing loads upon wire mesh and safety bars

Safety bars run perpendicularly between two beams to ensure that if a stored pallet is misaligned, it will be caught by the safety bars and won’t fall between the beams and through the rest of the system. Wire mesh and wire decking are other material falling prevention devices. If products are stored directly on them, check with the original manufacturer if they have the load capacity for your needs.

4. Welded Modifications

Welding is a common form of in-house modification or repair. While it is often done with the intent of repairing a component and returning racking to its original load capacity, it can cause more issues. Welding creates heat that affects the material properties of steel. In affected zones that may be weaker than their surroundings, paint can render welds impure if it is not adequately removed before the operation. These modifications are not recommended, but if you insist, they must be executed by certified welders and approved by engineers to maintain the original load capacity [2,4].

Figure 12: Examples of Welded Repairs On Pallet Racks

5. Improper Installation

Improper installation often creates situations where damage is more likely to happen over longer periods of time. Care should be taken when installing a new racking system to avoid the following issues.

5.1. Loose and Missing Anchors

When an anchor is missing, the column is not properly fixed to the floor. As such, there is no uplift resistance to counteract overturning forces, and the column is weaker regarding horizontal/ twisting forces. It can be easily pushed aside or twisted by passing equipment [1]. An upright's front and rear columns should be anchored according to what is specified in the rack’s stamped engineering drawings and calculations. The CSA even recommends using larger or additional anchors as a damage prevention method [1]. Having at least two anchors per column “helps prevent the column from pivoting upon impact” [3].

The same concerns mentioned for missing anchors apply to lose or poorly installed anchors as they do not provide the clamping force needed to keep the column grounded. To alleviate the issue, loose anchors can be tightened. Poorly installed anchors would need to be replaced or adjusted accordingly.

5.2. Leaning Racks

In some warehouses, the floor is angled or uneven. This situation can cause racks to stand at an angle that is not perfectly straight. As loads are added, the angle will only accentuate. Such cases often result in racks exceeding the maximum inclination tolerance (1”/240”) [3], which exerts additional stresses on the anchors as they must fight harder to keep the system grounded against the overturning forces. This issue can be rectified by adding shims below the racking in specific locations.

These shims are occasionally installed loosely or pushed out of place by passing equipment. The baseplate is therefore not fully resting on a flat surface. The shims would need to be pushed back in the appropriate position to avoid the rack from resting on an uneven surface.

5.3. Improper Bracing

Certain manufacturers create racking with bolted-on bracing. This bracing must be installed in a predetermined pattern to maximize load capacity. Deviation from the designed pattern reduces the bracing’s ability to counteract forces of tension and compression, which may result in lowered load capacities.

5.4. Missing Safety Pins/Bolts

Figure 13: Missing safety pin

Safety pins or bolts are devices that are passed through holes in both the beams connectors and uprights of a rack. If a beam were to be uplifted accidentally by a forklift, these devices would help prevent it from becoming unhinged or completely detached. An unhinged or partially detached beam carrying weight is hazardous, as material may fall. Since the weight isn’t being supported in the intended way, it could also deform the holes in the columns. This type of issue can make it difficult to reattach the beam correctly.

6. Encumbered floor

Impacts from moving equipment will likely happen in areas where maneuvering becomes tricky. A prime example would be a cluttered aisle with obstacles that an operator needs to maneuver to avoid. Keeping aisles clear of products or other encumbrances offers drivers maximum room to drive freely, thus reducing the potential for impact.

Keep your pallet racks in check for better warehouse safety

While impacts from forklifts are the most evident cause of pallet rack damage, there are more subtle sources of issues that can be equally detrimental to the longevity of your racking system. Corrosion can eat away at the steel of your racks, poor pallet loading, or overloading can overstress components, and improper installations can lower your load capacities or increase the risk of damage. To ensure your racks have as long a service life as possible, care should be taken to mitigate these factors.

Assessing your warehouse for pallet rack issues is the best way to protect your employees, merchandise, and building from incidents. If you are unsure about the conformity of your racking systems, Damotech experts can help you.

References

[1] CSA. (2005). User Guide for Steel Storage Racks/Standard for the Design and Construction of Steel Storage Racks A344.1/A344.2-05. Mississauga, Ontario: Canadian Standards Association.

[2] CSA Group. (2017). User Guide for Steel Storage Racks A344-17. Toronto, Ontario: Canadian Standards Association.

[3] CSST. (2005). Safety of Pallet Racks: Construction, Purchase, Installation, and Use. Commission de la sante et de la securite du travail du Quebec.

[4] Rack Manufacturer's Institute. (2014). Guideline for the Assessment and Repair or Replacement of Damaged Rack - Version 1.00. Charlotte, North Carolina: Rack Manufacturer's Institute.