Studies show poor racking steals up to 20% of usable cubes in North American warehouses. That’s the cost of renting an extra building every single year.

In this expert-backed guide, we compare the 8 most effective rack types, covering pros, cons, costs, and when to use each. This information will help you make informed, space-saving decisions that support safety and ROI.

You’ll learn:

- When each design shines (and when it fails)

- Pros and cons & cost

- Safety pitfalls that can double maintenance costs

This article is for you, whether you’re in the market for a new rack system or simply want to better understand the available options.

Scroll to find the rack layout that recovers square footage, accelerates throughput, and keeps your crew safe. Looking for quick answers? You can also jump to our FAQ section.

Selecting the Right Type of Pallet Racks

Selecting the type of rack to use in your warehouse can be challenging. A well-designed warehouse pallet racking system can help optimize available space and throughput while ensuring operational productivity and safety.

What Are the Different Types of Pallet Racking in a Warehouse?

There are two main categories of racking systems commonly used in warehouses: static and dynamic. Each category has several types of systems. Each type of pallet racking system has unique advantages and disadvantages, and understanding these differences can help you select the best racking system for your specific needs.

Static Pallet Rack Types

Dynamic Pallet Rack Types

Static Racking System Designs

A static pallet racking system is built to be stationary (pallets do not move once put in place or retrieved). It is commonly used due to its adjustability and typically lower costs than dynamic systems.

Static racks include selective (single-deep), double-deep, cantilever, and drive-in/drive-through pallet racks.

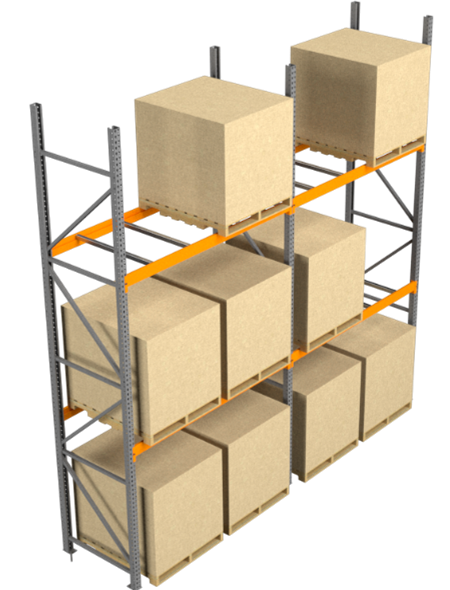

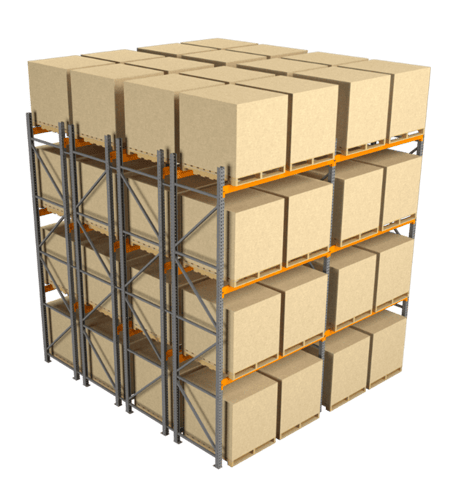

1. Selective Pallet Racks (Single-Deep)

Selective (single-deep) pallet racks are the most commonly used pallet rack systems in warehouses. They are cost-efficient and the least expensive compared to other rack types. These racks offer adjustability and are an ideal option for storing different kinds of products.

Figure 1: Selective rack (single-deep)

The rack’s beam heights and bay widths can be adjusted to accommodate pallets of various sizes and weights. They are often configured in back-to-back rows to conserve aisle space.

Advantages:

- Inexpensive compared to other rack types.

- Immediate access to all storage locations.

- Easy to modify (engineering approval required).

Disadvantages:

- Apart from setups with very narrow aisles (VNA), not very dense as they require multiple aisles.

- Costly for high-volume storage; many racks and ample warehouse space required.

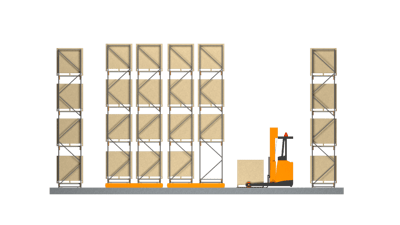

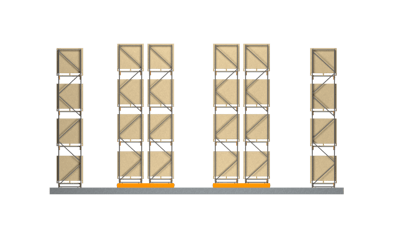

2. Double-Deep Pallet Racks

Double-deep racking systems are similar to selective (single-deep) racking systems in their core components, but they have a key difference: they feature an added second row. This design enhances storage capacity, making it suitable for items with high inventory levels.

Figures 2 and 3: Double-deep rack (side and top view)

Double-deep racks are mainly used for cold storage to maximize space and cost or dry storage where expiry is not a concern. This racking requires a specialized deep-reach forklift truck for loading and unloading due to its two-load-depth configuration.

Figure 4: Back-to-back double-deep racks

Advantages:

- Compared to single-deep racking systems, double-deep racks have increased storage density.

- Cost efficient – Fewer aisles while allowing more storage capacity at a lower cost.

Disadvantages:

- Require deep-reach forklift trucks to access pallets on the second row.

- Reduced accessibility – Access to rear pallets becomes more challenging, as it requires moving the front pallets first, leading to slower inventory retrieval times.

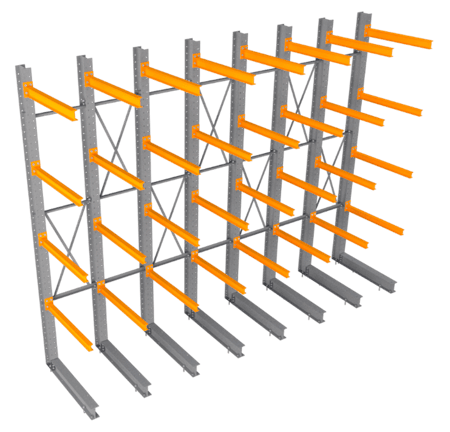

3. Cantilever Pallet Racks

Cantilever racks are specialized racks that provide a space-efficient storage solution for long and bulky items, like PVC pipes, steel sheets, and lumber. They are constructed from vertical columns, braces, arms, and bases. Depending on their design, cantilever racks can be used for light—to heavy-duty applications.

Figure 5: Cantilever rack

Cantilever racks are assembled in two possible configurations: single-sided or double-sided. Single-sided racking is only accessible from one side and is typically built against a wall. Double-sided racks provide direct pick access from both aisles, back-to-back, where the same column is used with arms on both sides. These racks are frequently found in plumbing supply warehouses, lumber yards, and shipping yards.

Advantages:

- Ideal for storage of long/bulky loads

- Variable storage capacity, from light to heavy-duty products.

- Quick storage and easy retrieval of products.

Disadvantages:

- High capital cost compared to other storage racks.

- Considerable floor space required for safe forklift access.

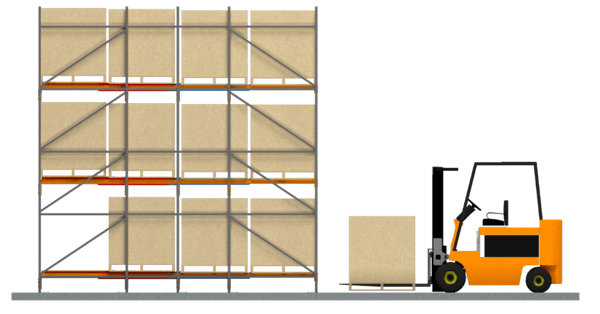

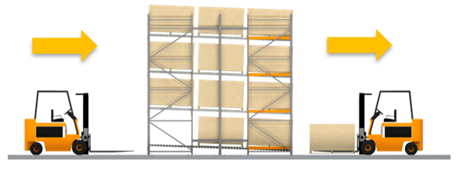

4. Drive-In and Drive-Through Pallet Racks

Drive-in and drive-through (sometimes called drive-thru) rack systems offer high-density storage capacity by maximizing warehouse space. These racks are called “drive-in/through” because forklifts must drive directly into the rack structure to access and place pallets on the rails that span the depth of the structure.

Drive-in pallet racks have a single entry and exit point on one side of an aisle. Drive-thru racks have an entry and exit point on opposite ends of the system, allowing forklifts to enter the rack structure from the front or the back.

Drive-in and drive-through bays are often arranged side-by-side to maximize the warehouse floor space and height, and each bay-level depth can hold multiple pallets. Considering the high storage capacity, this is a highly cost-effective racking system compared to the other racks.

Figure 6: Drive-in rack

A drive-in rack system operates in LIFO (last in, first out) stock rotation: the last pallet deposited in a slot will be the first to be unloaded. Since the forklift has one access point for each aisle for loading/unloading the pallets, you can install the rack against a wall. Due to its low rotation, this system is common in cold storage units and freezers.

By contrast, a drive-through rack system operates in FIFO (first in, first out) stock rotation: the first pallet deposited on the racking will be the first to be unloaded. The forklift can access both ends of the aisle, one for loading and the other for unloading. The racks must be installed in the warehouse aisles, not against a wall.

Figure 7: Drive-through rack

Advantages:

- Warehouse space optimization.

- Cost-effective, high-density rack systems.

- Significantly less square footage required compared to selective pallet racks.

Disadvantages:

- Not ideal for facilities with many different products.

- Prone to damage since forklifts enter the rack.

- Not flexible in design; standard pallet sizes required.

Not sure which rack type is right for you? Jump back to the full rack list ↑ or compare all in the cost table ↓.

Dynamic Racking System Designs

There are two types of dynamic rack systems: gravity racks and mobile racks. Gravity pallet racks, either Push Back or Pallet Flow, are designed with levels on an incline, and the racks are resting on wheeled carts or rollers. Mobile racks are selective single-deep racks mounted on wheels. They operate using a motorized unit, which allows the rack’s rows to be moved on slab-level rails.

1. Push Back Pallet Racks

A push back racking system is a high-density storage system with a stock rotation method similar to a drive-in racking system: LIFO (last in, first out). The main difference is that the pallets are loaded onto a gravity-fed wheeled cart system that rolls on an inclined rail in each lane. The forklift has one access point for each location for loading/unloading pallets.

Figure 8: Push back rack

To load, place a pallet on a rolling cart. The cart is then pushed back into the system each time an additional pallet is loaded. Due to the incline, the carts roll down to the aisle position and are held in place by the structure when a pallet is removed. The incline makes this rack system significantly faster to load and unload than a drive-in rack system.

Advantages:

- High-density storage capacity.

- Lower rack damage because forklifts do not enter rack structures.

Disadvantages:

- Costly compared to a drive-in pallet rack system.

- Higher maintenance and lifetime service costs for the rolling cart system.

2. Pallet Flow Racks

Pallet flow racking is a high-density storage system with pallets on roller conveyors. The stock is rotated on a FIFO (first in, first out) basis, similar to a drive-through rack system. The difference is that pallet flow racks are operated on an inclined gravity-induced roller system, and forklifts cannot enter the racking system.

Figure 9: Pallet flow rack

Pallet flow racking systems have forklift access at two ends of the system, one for loading and the other for unloading. The pallets are loaded onto rollers at one end, which are moved by gravity to the front of the system for easy unloading.

Advantages:

- Increased worker productivity - reduced travel time to load/unload.

- Quick inventory turnover through FIFO (first in, first out).

Disadvantages:

- High initial capital investment.

- Regular maintenance of the braking system.

- Pallets must always be in good condition to prevent jams.

Carton flow racks are essentially pallet flow racks, but they are used for picking up small boxes instead of pallets. They are mostly integrated with selective racks to create a dynamic hybrid system to support both pallets on the upper levels and picking on the bottom levels. Both carton flow and pallet flow racks share functionality but serve different purposes.

Figure 10: Carton flow rack

3. Mobile Pallet Racks

Mobile racking is a compact storage rack on a rail system attached to the floor. The racks are on wheels that move along the floor rails and are aligned with each other to save space.

Figures 11 and 12: Mobile racks

Adjacent rows are moved using a motorized unit to access an aisle. It is possible to incorporate various safety features (such as audible or visual alarms) into the system to minimize risks of collapse and workplace incidents. Mobile racking is an ideal storage solution in situations with space restrictions.

Advantage:

- Space-efficient since it requires less space than selective racking.

Disadvantages:

- High installation and maintenance costs.

- Typically requires increased safety measures.

- Additional time required to move rows before accessing pallets.

Need a refresher? Back to rack types ↑ or skip to the FAQ ↓.

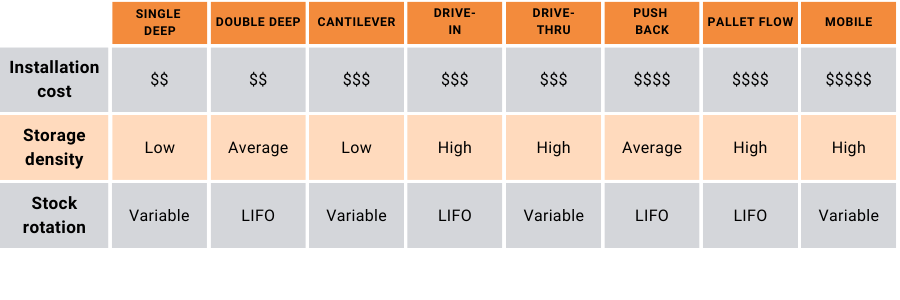

Comparison of All Industrial Pallet Rack System Types

The table below compares all the rack types discussed based on different selection criteria.

Selecting a Type of Pallet Rack Based on Warehouse Requirements

In conclusion, pallet rack systems are crucial components in warehouse storage and the organization of goods. There are several categories and types of pallet rack systems, each with unique advantages and disadvantages, and best suited for specific merchandise and storage needs.

Carefully choose the right pallet racking system for your warehouse needs. Consider products, warehouse space, and cost when making your selection. With the right pallet racks in place, you can create an effective warehousing system and improve your warehouse’s productivity.

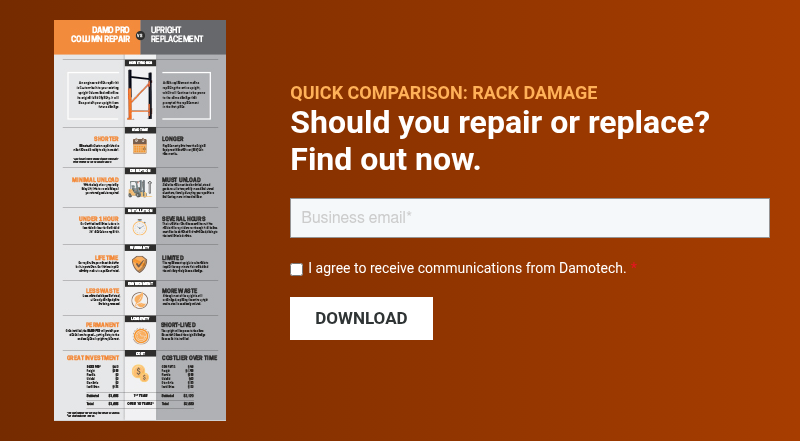

Remember that regardless of the type of racks you choose, they must always be in safe working condition. To assist with this, Damotech offers various free tools that can help you assess the condition of your racking systems and identify any potential hazards. By utilizing these resources, you can take the necessary steps to ensure that your pallet racks are safe and reliable for your employees and your business.

Drive-in racks are best for cold storage. Learn more about drive-in racks.

FAQ: Everything You Need to Know About Rack Types

Which racking system is best for cold storage?

Drive-in racking systems are the most effective solution for maximizing space in cold storage environments. They offer high-density storage with fewer aisles, making them ideal for facilities where space is at a premium and product rotation is minimal (LIFO).

Superior Space Utilization:

- Drive-in racks can utilize up to 70% of warehouse space efficiently

- They can accommodate up to 75% more pallets than selective racking systems in the same space

Energy Efficiency Benefits:

- Drive-in systems are particularly well-suited for cold storage environments due to their energy-saving characteristics

- The high-density storage design helps maintain consistent temperatures by reducing the air space that needs to be cooled

Real-World Evidence:

- Case studies show significant cost savings. For example, Coloma Frozen Foods implemented drive-in racking and achieved up to 75% more pallet storage than selective racking, with projected annual savings of $200,000.

While double-deep racking is also suitable for cold storage and can increase storage efficiency by up to 40%, drive-in systems offer superior space utilization for cold storage applications.

What is the average cost of a cantilever rack per bay?

In the USA, the average cost of a cantilever rack per bay typically ranges from:

- $500 to $1,000 for light-duty applications (e.g., PVC pipes, plastic tubing)

- $1,000 to $2,500+ for medium to heavy-duty systems (e.g., steel beams, lumber, industrial coils)

Factors that affect cost:

- Arm length and capacity (longer, heavier = higher cost)

- Number of arms per column

- Single-sided vs. double-sided configuration

- Finish type (e.g., galvanized for outdoor use)

- Installation & freight (often charged separately)

A good benchmark for an average warehouse using standard-duty double-sided cantilever racks is around $1,500–$2,000 per bay, installed.

Cost-Saving Options:

- Used cantilever racks can save up to 30% compared to new systems

- Refurbished options are available through various suppliers

For the most accurate pricing, it’s recommended to:

- Request quotes from multiple suppliers

- Consider both new and used options

- Factor in installation and additional costs

- Account for regional variations in pricing

The market for cantilever racking systems is projected to grow significantly, with the global market valued at USD 1.25 billion in 2024, which may influence future pricing trends.

Do pallet flow racks require special pallets?

Yes, pallet flow racks have strict pallet requirements to function properly and safely. Using the wrong type can cause jams, damage the system, and increase maintenance needs.

Recommended Pallet Type:

- GMA-style pallets (40" W x 48" D x 6.5" H)

- Minimum load capacity: 2,500 lb

- 4-way forklift entry required

- Must meet Grade A or B standards

Pallets Must Be Free From:

- Broken or missing boards

- Protruding nails

- Warping or damage

Best Practices:

- Test pallet types with your specific system before the full rollout

- Conduct regular pallet inspections

- Remove damaged pallets from circulation

- Adjust racking design as needed for your environment and pallet type

- Bay width needs additional clearance

What are the safest types of pallet racks?

Selective (single-deep) pallet racks are generally considered the safest due to their simple layout and direct access to all pallets. They reduce forklift maneuvering complexity and minimize rack impact risks. Additionally, push back and pallet flow systems are safer than drive-in racks because forklifts don’t enter the racking structure, lowering the risk of structural damage.

How do I choose the right pallet racking system?

Start by assessing your inventory turnover, product size, space constraints, and equipment.

For example:

- Use selective racks for varied SKUs and high accessibility.

- Choose drive-in or push back racks for high-density storage.

- Opt for cantilever racks for long or irregularly shaped items.

Consulting with an engineer or racking expert can help ensure your choice balances space optimization, safety, and budget.

Which pallet racking system is most space-efficient?

Mobile racks are the most space-efficient, eliminating fixed aisles and allowing compact storage. However, they come with higher installation costs. Drive-in, push back, and pallet flow racks also offer excellent density, especially in cold storage or high-volume environments.

Can I mix different types of pallet racks in the same warehouse?

Yes, many warehouses use a hybrid racking approach to meet diverse storage needs. For example, selective racks may be used for fast-moving products, while drive-in or pallet flow racks store bulk items.

Mixing rack types can improve space utilization and operational flexibility. In fact, a documented case study showed a 38.25% increase in efficiency after a company implemented a hybrid system combining push back and drive-in racks.

What are the main differences between static and dynamic pallets, and how does each type impact warehouse efficiency and space utilization?

Static pallets remain in fixed positions within a racking system, requiring forklifts to place and retrieve each load manually. They are commonly used in selective racking and drive-in racking, where pallets do not move once stored. In contrast, dynamic pallets are designed to move within the racking structure using gravity-fed rollers or push-back mechanisms, enabling more efficient stock rotation. These are found in dynamic racking systems like push-back racking and pallet flow racking, optimizing space utilization and improving loading and unloading speed.

Content References

- https://www.srs-i.com/blog/advantages-disadvantages-cantilever-racking/

- https://www.mazzellacompanies.com/learning-center/warehouse-racking-pallet-rack-systems-different-types-design/

- https://www.mskcanada.com/en/blog/5-advantages-of-high-density-industrial-mobile-shelving

- https://www.super-racking.com/info/advantages-and-disadvantages-of-mobile-shelves-51912413.html

- https://mallardmfg.com/pallet-flow-racking-vs-simple-selective-pallet-rack-when-why

- https://www.ar-racking.com/en/news-and-blog/storage-solutions/storage-racking-solutions/types-of-industrial-racking-for-the-warehouse-classification-and-characteristics

- https://arnoldmachinerymh.com/pallet-racking/push-back/

- https://www.warehousestoragesolutions.com/push-back-pallet-racking-what-is-it

- https://www.commander.ca/product-push-back-pallet-racking/

- https://gujratsteel.com/advantages-and-disadvantages-of-drive-in-racking-systems/

- https://www.ar-racking.com/en/news-and-blog/storage-solutions/storage-racking-solutions/differences-between-drive-in-and-drive-through-racking

- https://www.ar-racking.com/en/news-and-blog/storage-solutions/storage-racking-solutions/types-of-industrial-racking-for-the-warehouse-classification-and-characteristics

- https://ecseco.com/blog/single-vs-double-deep-selective-rack-which-is-the-best-option-for-you/

- https://phindustry.com/2016/08/07/top-benefits-of-single-deep-pallet-racking/

- https://vestrainet.weebly.com/blog/selective-racking-advantages-and-disadvantages

- https://advancestorageproducts.com/4-advantages-to-utilizing-double-deep-selective-pallet-racking-in-your-warehouse

- https://www.mskcanada.com/en/blog/5-advantages-of-high-density-industrial-mobile-shelving

- https://ecseco.com/blog/stackable-racking-types-and-use-cases/

Figure References

- Figure 7: https://www.cssyes.com/product/twinlode-drive-in-pallet-rack/

- Figure 10: http://3dlogistic.ca/carton-flow/