So, can anyone install pallet racking?

Technically, anyone can attempt pallet rack installation. But installing a structural storage system that supports thousands of pounds at height is very different from assembling household furniture from a well-known Swedish store. Pallet racking is an engineered structure that is governed by safety standards, load capacity calculations, structural requirements, and building codes.

While it may seem simple, proper pallet racking installation requires more than bolts and beams. It demands specialized knowledge and technical expertise to ensure the racking is installed correctly and safely. When installed incorrectly, the consequences can include reduced load capacity, rack collapse, damaged inventory, and serious worker injury.

This isn’t just an installation task — it’s a safety decision.

What Do Safety Standards Say About Pallet Racking Installation?

ANSI (American National Standards Institute), RMI (Racking Manufacturing Institute), and CSA (Canadian Standards Association) recommend that pallet racking installation be performed by experienced, properly trained personnel. This ensures systems are assembled safely, efficiently, and in compliance with all applicable regulations.

While pallet rack installation requires specialized knowledge, it is a skill that can be developed. New installers can build competency through hands-on training, mentorship, and a strong understanding of safety standards and best practices.

Why Expertise Matters in Pallet Racking Installation

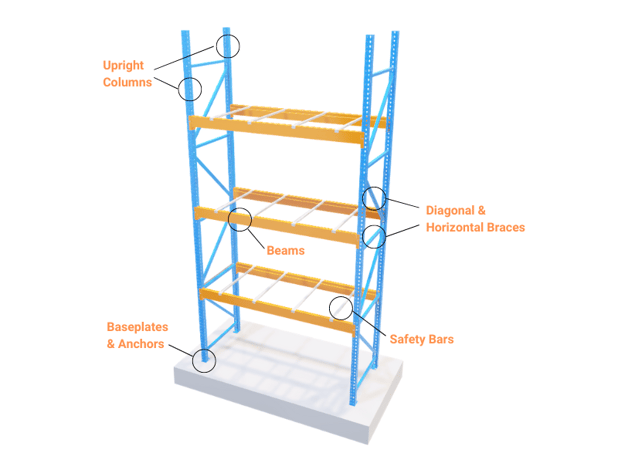

Understanding Rack Components

Installers must understand the function and correct placement of key components — including uprights, beams, braces, baseplates, and anchors. Incorrect assembly can compromise the entire system.

Compliance With Safety Standards

Pallet rack installation must comply with applicable local building codes and national standards (e.g., CSA, ANSI, and RMI). This may also require engineering documentation and proper permitting.

Structural Integrity and Stability

Improper installation can reduce structural performance and increase the risk of failure under load. Uprights must be plumb, properly anchored, and shimmed where required to maintain stability and load distribution.

Load Capacity Performance

Installation directly affects load capacity. Beam spacing, anchoring configuration, and rack configuration must match the approved load application to ensure the system safely supports intended loads.

CSA and ANSI Requirements for Warehouse Racking Installation

Navigating CSA, ANSI, and RMI specifications can feel overwhelming—like reading a foreign language that demands patience and focus. However, understanding these standards is crucial for ensuring the safety, compliance, and structural integrity of pallet racking systems. While we won’t dive into every detail here, knowing the basics of these standards is essential for successful pallet rack installation.

Recognized industry standards, including ANSI, RMI, and CSA specifications, govern pallet racking installation. These define the minimum requirements for design, anchoring, load capacity, and structural performance to ensure racks operate safely and remain compliant with applicable regulations.

Although the standards are technical, understanding their core principles is critical. Even a basic awareness of these requirements helps ensure pallet racking systems are installed correctly, maintain their intended load capacity, and reduce the risk of structural failure.

Table: CSA, ANSI, and RMI Requirements

| Specification | Key Requirements | Applicable Standards |

|---|---|---|

| Pallet Rack Installer Capabilities |

|

CSA A344 Section 6.1 RMI (ANSI MH16.1) Section 4.4 |

| Instructions and Installation Drawings |

|

CSA A344 Section 6.2.1 RMI (ANSI MH16.1) Section 4.2 |

| Load Plaques and LARC (Load Application and Rack Configuration Drawings) |

|

CSA A344 Section 7.3.2 RMI (ANSI MH16.1) Sections 4.5 & 4.6 |

| Post-Installation Inspection |

|

RMI (ANSI MH16.1) Section 4.3 |

| Final Inspection Before Use |

|

RMI (ANSI MH16.1) Section 4.9.4 |

Reconfiguration of Pallet Racking Systems and Engineering Approval

All drawings and specifications are established at the time of installation and must be followed. Any deviation from the manufacturer’s detailed drawings requires approval from a qualified engineer.

CSA, RMI, and ANSI require engineering review when pallet racking systems are relocated or beam elevations are modified, as these changes can affect load capacity. In such cases, recertification is necessary to ensure the continued safety and stability of the racking system.

Talk to an Engineer Before Reconfiguring

Pallet Rack Installation: Simple Steps to Keep Things in Check

Understanding the steps involved in erecting a pallet racking system is crucial for ensuring safety, stability, and long-term reliability. Proper installation not only helps prevent structural issues but also ensures the system can withstand the intended loads and usage.

Below is a comprehensive overview of the process, covering everything from site preparation and leveling to assembly and final adjustments — all while maintaining the integrity and performance of the racking system.

1. Prepare the Workspace

Before starting, ensure the workspace is ready for installation:

- Clear the area: Remove any debris, equipment, or obstacles.

- Inspect the floor: Verify that the surface is level, clean, and free of damage such as cracks or uneven spots.

- Mark the layout: Using the racking design plan, mark the positions of the uprights and beams on the floor. This step ensures proper alignment and spacing between the racks.

2. Assemble the Racking System

Uprights form the vertical structure of the racking system and must be assembled with care:

- Stand up two uprights and install the top beams to keep the uprights in place. Ensure the first diagonal brace faces the front.

- Install the remaining beams working downward toward the ground within that bay. Repeat this process for all the bays and systems.

- Use a measuring tape to confirm that the uprights are square and equally spaced.

- Use a bubble level to check that each frame is perfectly vertical (plumb). Misalignment at this stage can compromise structural stability.

- If necessary, install shims under the baseplate to correct for minor floor irregularities.

Figure 1: Ensuring the system is plumb Figure 2: First diagonal brace position

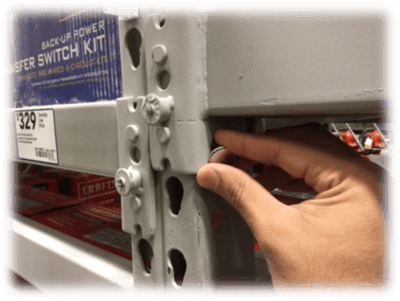

3. Install Safety Devices

Once all beams are installed, ensure they are equipped with appropriate safety devices to prevent dislodgement and maintain structural stability. For more information on the role and proper use of safety devices, please visit Pallet Rack Safety Pins: Extra Security in a Tiny Package.

Figure 3: Different types of safety devices Figure 4: Installing a safety pin

4. Anchor the Frames to the Floor

To ensure stability and prevent tipping, anchor the uprights securely to the floor. For information on anchoring requirements, please visit Pallet Rack Anchors: Small but Essential.

- Drill holes into the floor at the baseplates of each upright.

- Use a vacuum to remove debris and dirt from the drilled holes.

- Insert anchor bolts into the drilled holes and tighten them using a wrench or impact driver.

- Double-check that all bolts are firmly secured and that the frames remain level and plumb.

Figure 5: Expansion and screw anchors Figure 6: Installing anchors

5. Install Safety Accessories

Depending on the design and intended use of the racking system, install any additional components:

- Wire decking: Place wire mesh or solid decking across beams for added storage support.

- Safety bars: Add crossbars for enhanced support under heavy loads.

- Column guards: Install protective guards at the base of the uprights to help prevent forklift damage.

Figure 7: Damo Guard on pallet rack column Figure 8: Installing wire mesh decking

6. Inspect the Pallet Rack Installation

Once the racking is assembled, conduct a thorough inspection to confirm proper installation:

- Check all connections between beams, uprights, and braces.

- Ensure all locking clips or safety bolts/pins are securely in place on beams.

- Verify that the entire structure is level and plumb.

- Confirm that the racking layout matches the approved design plan.

Book a Professional Rack Inspection

7. Label and Organize

After installation and inspection, ensure the appropriate load capacity labels/plaques and Load Application and Rack Configuration (LARC) drawings are in place. For more information on LARCs, please visit Pallet Racking Weight Capacity: Why Warehouse Operators Need LARCs.

- Attach load capacity labels to each section of the racking. These labels must be clearly visible and comply with safety standards.

- For uniform racking systems, a single load capacity plaque may be installed at the end of the aisle on the side of the system.

- For non-uniform systems, load labels must be installed on the beams of each bay.

Figure 9: Loading plaque

The Bottom Line on Pallet Racking Installation

Proper pallet racking installation is essential to ensure safety, structural stability, and efficient warehouse operations. Following the correct steps — from site preparation and leveling to precise assembly and adjustments— helps prevent costly mistakes and ensures the system performs as designed.

Because pallet racks are engineered structures, proper pallet rack installation directly affects load capacity, compliance, and long-term durability. Taking the time to complete warehouse racking installation correctly will not only extend the lifespan of your system but also create a safer, more reliable working environment.

When it comes to installing pallet racking, the safety of your team and the integrity of your storage system depend on getting it right.

Before installing, relocating, or reconfiguring pallet racking, speak with a qualified rack engineer to ensure compliance, structural integrity, and proper load capacity certification.

When installation is required, our in-house team of certified installers serves facilities across North America, delivering pallet racking installation aligned with engineering requirements and industry standards.

References

Figure 3: Complete Storage System Solutions (n.d.) Konstant. https://www.konstant.com/en/shop/infrastructure-and-equipment-protection/safety-pins

American National Standards Institute [ANSI]. (2023). Design, Testing, and Utilization of Industrial Steel Storage Racks (ANSI MH16.1-2023).

National Standard of Canada [CSA]. (2024). User Guide for Steel Storage Racks (CSA A344:24).

Rack Manufacturers Institute [RMI]. (2012). Consideration for the Planning and Use of Industrial Steel Storage Racks (RMI-12).

Frequently Asked Questions About Pallet Racking Installation

Can anyone install pallet racking?

What do safety standards say about pallet rack installation?

ANSI, RMI, and CSA recommend that pallet racking installation be performed by experienced, properly trained personnel. Installation should be completed by a competent person who is regularly employed in erecting pallet racks. The selected company should be experienced in installing the specific type of storage rack system being installed.

These standards define minimum requirements for design, anchoring, load capacity, structural performance, inspections, and load plaques to ensure compliance and safety.

What does proper pallet racking installation involve?

Proper pallet racking installation involves site preparation, leveling, assembling uprights and beams, installing safety devices, anchoring frames to the floor, installing safety accessories, conducting inspections, and ensuring load plaques and LARC drawings are in place.

Uprights must be plumb, properly anchored, and shimmed where required. Beam spacing, anchoring configuration, and rack configuration must match the approved load application to ensure the system safely supports intended loads.

Why does expertise matter when installing pallet racking?

Expertise matters because incorrect assembly can compromise the entire system. Installers must understand the function and correct placement of uprights, beams, braces, baseplates, and anchors. Installation directly affects load capacity, structural stability, and compliance with CSA, ANSI, and RMI standards.

Improper warehouse racking installation can reduce structural performance and increase the risk of failure under load.

When is engineering approval required for pallet rack installation?

Engineering approval is required when pallet racking systems are relocated or when beam elevations are modified, as these changes can affect load capacity. Any deviation from the manufacturer’s detailed drawings requires approval from a qualified engineer.

In such cases, recertification is necessary to ensure the continued safety and stability of the racking system.

Are inspections required after pallet rack installation?