What Does “Plumb” Mean for Pallet Racking?

Montreal’s Olympic Stadium, the Tower of Pisa, and the Parliament Clock Tower “Big Ben” in London have something in common. These famous buildings lean. The Olympic Stadium leans intentionally by about 45 degrees, the Tower of Pisa by 3.99 degrees, and Big Ben leans by a mere 0.26 degrees.

Out-of-Plumb vs. Out-of-Straight Rack Uprights: What’s the Difference?

Out-of-Plumb Explained

To answer this question, let’s look at the definition of rack plumbness. Simply put, an upright that is perfectly vertical and straight is plumb.

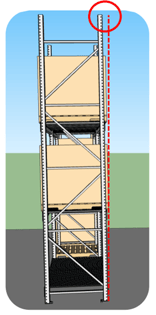

On the other hand, an upright is considered out-of-plumb when it’s leaning in any direction, whether it’s in the cross-aisle direction (from front to back) or in the down-aisle direction (from side to side).

Standards for Pallet Racking Stability: Upright Tolerances

US and Canadian standards (ANSI MH16.1 and CSA A344) are relatively straightforward regarding pallet racking stability. The threshold when the rack is loaded is 1/240, which amounts to 1/2" over a height of 10 feet or 12.5 mm over 3m. This maximum deviation applies to both front-to-back and side-to-side leaning. This is equivalent to less than 0.24 degrees of tilt. Anything above this is considered out-of-plumb and does not conform to standards.

For instance, the Tower of Pisa’s non-conformity is understandable since it very clearly leans; anyone would doubt its stability. However, most of you probably didn’t even know that “Big Ben” leaned. It’s not even noticeable to the naked eye, yet it falls outside of tolerance. Similarly, one upright out-of-plumb can be easily identified in a system.

However, detection becomes more challenging when all the uprights are out-of-plumb without any vertical reference, such as a roof-supporting column inside your warehouse. Therefore, it is recommended to use electronic levels to inspect an upright’s inclination, as they can help us see and measure things our eyes can’t.

Out-of-Straight Explained

Well, the same column verticality tolerance is used for pallet racking stability. While out-of-plumb racks are straight but lean, out-of-straight racks have unintended curving. Indeed, regardless of the reason for the curvature, the same maximum deviation tolerance of 1/2" over 10 feet (12mm over 3m) still applies. This equates to curvature of 1/20th of an inch per foot. Again, electronic levels and lasers help immensely evaluate out-of-plumb and out-of-straight issues on pallet racks.

Figure 2: Out-of-straight pallet rack upright

Common Causes of Rack Upright Misalignment

- Beam height changes or alterations

- Type of beam connection used

- Insufficiently tightened bolts at the time of installation

- Impacts with forklifts or pallets commonly found near the base of uprights

- Overloading the beams and racks

- Uneven floor level

If a pallet rack upright is out-of-plumb or out-of-straight, it must be unloaded and corrected to conform to the accepted tolerance. You should always look for the cause or the damage affecting your racks to lean or curve to better correct the issue and prevent it from occurring again.

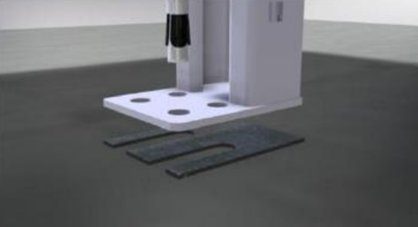

For instance, in the case of uneven floor level, it may be necessary to install baseplate shims, as shown in the figure below, to achieve a vertical stance. The steel leveling pads must match the full baseplate size and anchoring holes.

Figure 3: Baseplate shim

How to Inspect and Correct Your Pallet Rack Uprights

Given these points, it is always recommended to have all your racks inspected by experts in the field. Damotech offers a wide range of engineered rack solution services such as complete conformity inspections performed by engineers who are specialized in pallet racking and their safety.

Frequently Asked Questions: Pallet Rack Stability & Out-of-Plumb Uprights

What does “plumb” mean for pallet racking?

What is the difference between “out-of-plumb” and “out-of-straight”?

Both terms refer to vertical alignment but describe different conditions:

- Out-of-plumb: The entire upright leans like a tilted pole.

- Out-of-straight: The upright bows or curves along its height.

ANSI MH16.1-2023 sets the same maximum deviation ratio—1/240 (1/2" per 10 ft)—for out-of-straight columns. Electronic levels or lasers provide the most accurate way to measure these deviations, since small angles of tilt (less than 0.25 degrees) are barely visible to the naked eye.

What causes uprights to become out-of-plumb or out-of-straight?

Common causes include:

- Forklift or pallet impact near the upright base

- Uneven floor elevation or improper shimming during installation

- Loose anchor bolts or baseplates

- Beam-level changes that alter frame loading

- Overloading of beams or bays beyond rated capacity

- Improperly tightened bolts at assembly

These factors create cumulative stress and can gradually misalign the rack structure.

What should I do if an upright is out-of-plumb beyond tolerance?

Per ANSI MH16.1, the rack must be:

- Unloaded immediately

- Isolated from service

- Evaluated by a qualified storage rack professional before reuse

The engineer must verify that repairs or adjustments restore the rack to at least its original load capacity.

How can out-of-plumb issues be corrected?

If an uneven floor causes misalignment, install steel baseplate shims that:

- Match or exceed the baseplate footprint

- Are made of material equal to or stronger than the floor’s bearing strength

- Have a total thickness no greater than six times the largest anchor-bolt diameter

All shims must be secured to transfer shear forces effectively. If the lean results from impact damage, the affected upright should be repaired or replaced using engineered components.

How can I inspect rack plumbness accurately?

Best practices include:

- Using digital or laser levels for precision

- Checking both cross-aisle and down-aisle directions

- Recording all measurements during routine rack inspections

- Comparing readings against the 1/240 tolerance limit

If any measurement exceeds tolerance, or you are unsure, unload and consult a qualified rack engineer.

Why is maintaining plumbness essential for rack stability?

Both ANSI MH16.1-2023 and OSHA’s General Duty Clause (29 USC 654(a)(1)) require employers to maintain storage racks in a safe structural condition to prevent struck-by or falling-object hazards.

How can Damotech help if my racks are leaning or damaged?

Damotech’s engineering services include:

- Conformity inspections by licensed engineers trained in ANSI MH16.1 and CSA A344 standards

- Rack damage assessments and precise out-of-plumb measurements

- Engineered repair solutions and shimming plans

- Certification that repaired racks meet or exceed original design capacity

Damotech also offers a free rack damage assessment if you notice a damaged rack.