Next steps after fixing your pallet racks: How to prevent damage and accidents

Your storage systems play an important role in the efficiency of your warehousing activities. While it may seem overwhelming sometimes, keeping the integrity of your racking assets in check is easier than you may think. Once you’ve fixed the racks that needed attention, introducing damage prevention products and better habits will help prevent accidents and high repair or replacement costs.

The following 4 points are easy to implement and will help prevent accidents and damage to your racks!

1. Using fall prevention accessories

The correct use of fall prevention accessories can significantly minimize the risk of injury to workers, pedestrians, and damage to stored goods and equipment. The sales representative of the companies that sell these products can offer recommendations on the types of safety accessories, as well as where they should be installed in the warehouse to provide maximum safety benefits.

Three pallet and product fall protection items:

Safety bars are installed on load supporting beams to prevent pallets from partially or completely falling between beams, through the rack.

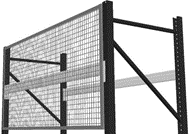

- Safety netting and wire mesh backers are used to prevent items from falling into a workspace or aisle way located behind the rack.

-

Wire-mesh decking is placed in between and over beams and can prevent boxes accidentally knocked off a stored pallet from falling through.

2. Preventing recurring issues in my warehouse

Warehouses will typically have several types of issues that could be caused by various factors. However, if one type of issue seems to occur frequently, it could indicate a systematic error in the way activities are conducted in the warehouse. If this is the case, determining the root cause and addressing the problem can prevent such issues from re-occurring and directly benefit the maintenance of your warehouse storage systems.

Because the issues tend to vary from warehouse to warehouse, experts can provide solutions tailored to your specific warehouse, e.g., providing a solution to the most observed damage in your specific storage systems.

Three of the most common warehouse storage system damages resulting from bad practices:

-

Not respecting the clearance between pallets and racks (flue space), which increases the chances of damaging the braces. The recommended flue space (i.e., empty space) in between pallets and between a pallet and the upright frame is at least 3 inches. This means there should be at least 3 inches of clearance between an upright and a pallet.

Figure 1. Correct flue space

Not only is respecting the flue space critical in preventing damage to bracing, but it also allows water to trickle down the racks in the event of a fire. Further, not leaving appropriate clearance between pallets may also block the heat from traveling up the racks, which delays the sprinklers from activating. Thus, keeping the flue space in mind when loading racks ensures the proper functioning of the sprinklers and prevents damage to the upright.

-

Loading stack sticks directly on the arms of cantilever racks, which leads to deformation of the arm base and/or of the column.

Figure 2. Stack sticks placed directly on arms (not recommended)

This is a bad loading practice that leads to an uneven load distribution, which can overload the arm supporting the stack stick. When loading products onto cantilever arms, care should be taken such that stack sticks are not placed directly on arms while ensuring even load distribution.

-

Forklift impacting uprights, which leads to deformed and sheared columns and baseplates.

Figure 3. Forklift impact that deformed the column and baseplate, rendering it unusable.

The occurrence of such damage can be greatly reduced by proper training of forklift drivers and by exercising caution and reducing speed while operating in aisles. Further, this can also help to reduce the recurrence of damages to low-level bracing and to the bottom part of uprights, while reinforcing a culture of safety within the workplace.

3. Protecting warehouse racking

Some racks in the warehouse may be more vulnerable to damage than others due to their placement, layout, and the type of supported load. Knowing how and where warehouse racks should be protected is essential to extending the life of your storage systems. Pallet rack upright protection extends the life of your storage systems by preventing direct impacts from forklifts. This is especially true in high-traffic areas such as shipping and receiving and on racks located at the end of aisles.

Damotech's rack experts can work with you to pinpoint the areas where rack upright protection can be beneficial to the upkeep of your storage systems. Choosing the right product to protect your racks is equally important as knowing where to install them. Damotech offers a wide range of efficient and cost-effective rack protection products:

The Damo Guard is designed to protect the areas of a rack upright at high risk of impact, reducing frontal and lateral impact stresses felt by the column by a factor of 6 and 9 respectively while being inexpensive. These can be installed to protect the bottom part of the rack uprights in areas with high forklift circulation, narrow aisles, end caps, and anywhere a pallet rack is at high risk of forklift impact.

The Damo Guard is designed to protect the areas of a rack upright at high risk of impact, reducing frontal and lateral impact stresses felt by the column by a factor of 6 and 9 respectively while being inexpensive. These can be installed to protect the bottom part of the rack uprights in areas with high forklift circulation, narrow aisles, end caps, and anywhere a pallet rack is at high risk of forklift impact.

-

The Damo Base Guard conveniently protects the bottom part of pallet racking columns. The low and unobtrusive design of the base guard allows the installation and removal of floor-level beams.

-

End-of-aisle rack uprights are typically the most vulnerable to impact damage due to forklift traffic. The Damo End Guard is a 3/8" thick angle iron with stiffeners made-to-order that offers excellent floor-level protection for the end of aisle racks.

4. Protecting warehouse building components

Warehouse building components are usually only designed to support the building structure.

Warehouse building components are usually only designed to support the building structure.

Figure 4. Sprinkler damaged by a forklift

As such, care should be taken to protect these from traffic impacts and/or additional loads from neighbouring structures e.g., pallet racks. Warehouse building components include sprinkler systems, columns, walls, and beams. These components should be well protected from storage systems and forklift traffic to avoid unwanted consequences.

The first level of protection is spacing i.e., keeping a distance between them and neighbouring structures. This leaves room for potential movement and vibrations caused by operation or seismic activity. Additional proactive protection can be added to building structures to shield them from moving traffic e.g., forklifts or other machinery.

Damotech's protection products designed to shield your warehouse building components

-

The Damo Shield offers heavy-duty protection against impacts from forklifts, trucks, or any other kind of machinery or vehicle. It is designed to be installed completely independently from the column it protects. This means that the shield absorbs the impact, ensuring that the column remains intact.

-

The Damo Fence provides protection for your building components against impacts from forklifts, trucks, or any other kind of machinery or vehicle. The fence’s parts being welded and it being solidly anchored makes it highly resistant to impacts. It is engineered and built using heavy gauge structural steel for high impact resistance.

-

The Damo Guardrail is of similar construction but is optimized to protect pedestrians.

-

Pallet stoppers are used to protect walls or drive-in racks’ back frames against pallet impact at floor level. They can also be used to protect front beams in double-deep drive-in racks as outrigger stoppers. In this case, rubber is added at the front of the stopper to avoid damaging the outriggers.

Good practices regarding the protection of your pallet racks will lead you to simplified warehouse management, a reduction in repair or replacement costs, and overall awareness of your team about safety at work!

-

References:

Lowe’s Rack Inspection Statement of Work No.2, page 1

Damotech blog posts:

With So Many Rack Safety Products to Choose From, Where to Start?

How to Assess and Identify Pallet Rack Damage