Beyond the everyday operations, there are intriguing facts about the warehousing world, spanning from the towering heights of clad rack warehouses to impressive world records. This blog explores some intriguing facts about warehouses, both from a structural and operational perspective.

FACT #1: Tallest Clad-Rack Warehouses

Clad rack warehouses use racking as the foundation for the building. These remarkable structures can be likened to the skyscrapers of the warehouse industry.

EMS-CHEMIE AG is a Swiss-based company specializing in polymer materials and fine chemicals. Their impressive state-of-the-art facility boasts fully automated industrial pallet handling systems that can manage pallets up to 146 feet, offering storage for 12,800 pallets. It is one of the industry’s tallest clad rack warehouses, constructed with 1,000 tons of steel, 500,000 screws, 11 kilometers of supporting columns, and 55 kilometers of pallet carriers.

Figure 1: EMS-CHEMIE AG in Switzerland.

Even more remarkable is the clad rack warehouse of Hayat Kimya, a chemical company in Turkey and Eurasia. Its dimensions far exceed those of a typical warehouse, soaring to a towering height of 151 feet, with a length of 394 feet and a width of 344 feet!

Due to the seismic risk in the area, they used a total of 10,000 tons of steel, with an extra 2,000 tons for added seismic strength. This warehouse can store 161,000 pallets. To give you an idea, if these pallets were placed in a line, they would stretch over 193 kilometers!

Figure 2: Hayat Kimya in Turkey.

FACT #2: Largest Distribution Warehouse in the World

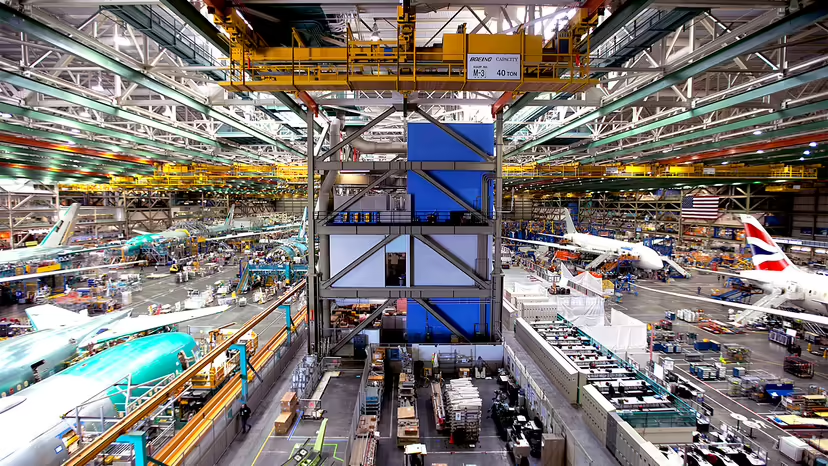

Situated in Washington, the Boeing Everett Factory stands as the largest warehouse in the world by usable volume, exceeding 470 million cubic meters, with an astonishing 4 million square feet of floor space specifically designed for the assembly, machinery repair, and transportation of components for Boeing’s iconic aircraft.

Fun Fact: Before the construction of this warehouse in 1967, the building with the largest volume was held by the NASA Vehicle Assembly Building.

Figure 3: Boeing Everett Factory in Washington, USA.

FACT #3: Largest Warehouse Landlord Worldwide

Prologis, a global leader in industrial real estate, manages a vast portfolio of over 1.2 billion square feet of warehouses and distribution centers worldwide that serve prominent companies such as Amazon, Home Depot, and FedEx. Rather than simply renting out space to their tenants, they collaborate closely with them to customize properties and services, aiming to support and enhance their business objectives [1].

Figure 4: A Prologis warehouse.

FACT #4: Leading Cause of Injuries in Warehouses

One of the most common causes of non-fatal injuries in warehouses is “slips, trips, and falls.” According to the U.S. Department of Labor, these accidents contribute to 15% of all accidental fatalities, 25% of all reported injury claims, and an astonishing 95 million lost workdays annually [2]. They hold the top position not only within warehouses but across all industries.

These incidents can result from various factors, including wet or slippery floors, cluttered pathways, uneven surfaces, inadequate lighting, and improper footwear. Hazards such as discarded boxes, box ties, cables, or spilled substances can all cause injury.

To prevent such injuries, warehouse operators should implement safety measures, including:

- Maintaining clean and dry floors.

- Conducting regular safety inspections.

- Providing proper signage.

- Train employees in proper lifting techniques and safe navigation within the warehouse.

It’s important to note that safety practices and regulations can vary by location and may change over time, so it’s crucial to stay updated on the latest safety guidelines in your specific area.

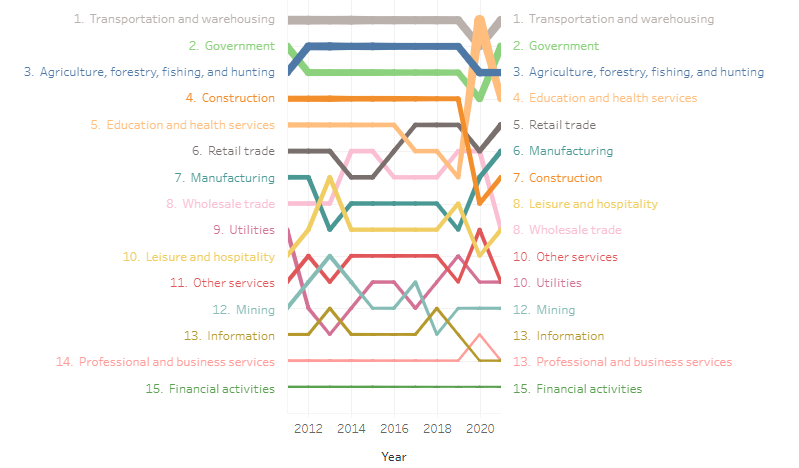

FACT #5: Transportation and Warehousing Ranked as the Most Dangerous Industry

The question “Which industry is the most dangerous?” frequently arises. However, because “workplace danger” can be defined in various ways, there is no one answer to this simple question.

Figure 5: Rank by non-fatal injury and illness rates from 2012 to 2020.

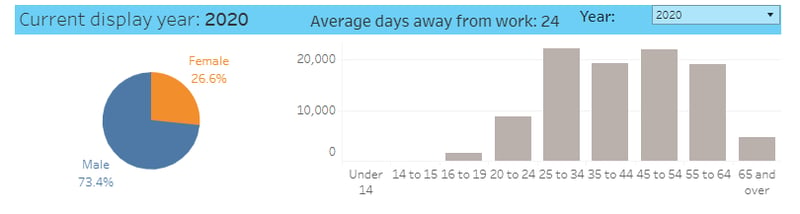

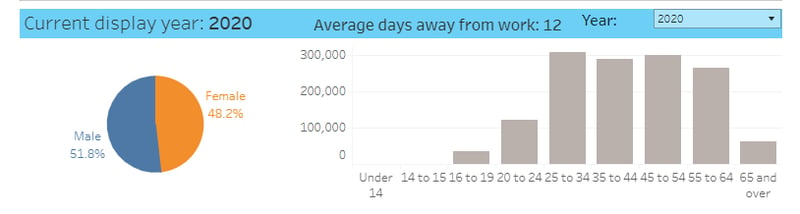

In 2020, the transportation and warehousing sector could be characterized as one of the most hazardous industries, as it recorded the highest rate of injuries and illnesses resulting in days away from work per 10,000 workers. As depicted in Figures 6 and 7 below, the average amount of time away from work was twice the average for all industries combined.

Figure 6: Average days away from work—Transportation and warehousing industry.

Figure 7: Average days away from work—All industries combined.

Additionally, the U.S. Bureau of Labor Statistics discovered that the non-fatal injury rate in 2020 significantly exceeded the average for all industries. Specifically, there were 4.8 injuries per 100 workers in warehousing and storage compared to the 2.7 injuries per 100 workers for all sectors combined.

FACT #6: Most Dangerous Area in a Warehouse

Loading docks can be very risky for warehouse workers. According to OSHA, about 25% of all warehouse accidents occur here, and there are nearly 600 close calls for each injury.

Workers at loading docks face various dangers, like falling off, getting hit by trucks or forklifts, and getting hurt while moving heavy things. Open loading docks, when not in use, can be dangerous. Although the drop might not seem very high (about four feet), it can cause severe injuries if someone falls or drives off the edge with a forklift. They can also be at risk of carbon monoxide poisoning if they spend a long time near running trucks.

Injuries at loading docks hurt workers and cost companies a lot through worker compensation, lower productivity, and lost work hours.

Here are some safety tips:

- Use vehicle restraints to keep trailers secure.

- Get indicator systems with lights to show when it’s safe for trailers to leave the dock and for workers to load or unload.

- Use dock levelers to reduce vibrations for workers handling freight.

- Make sure there’s enough light inside trailers.

- Close gates on open dock doors when there are no trailers.

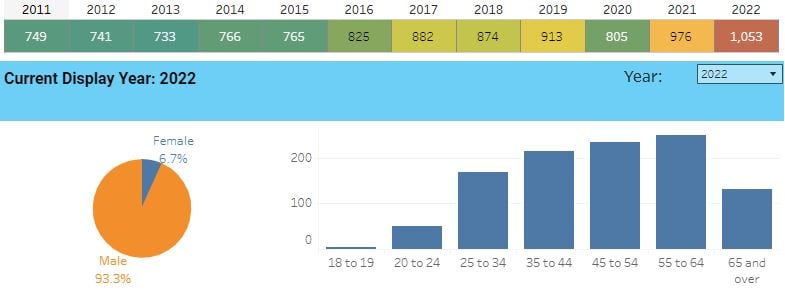

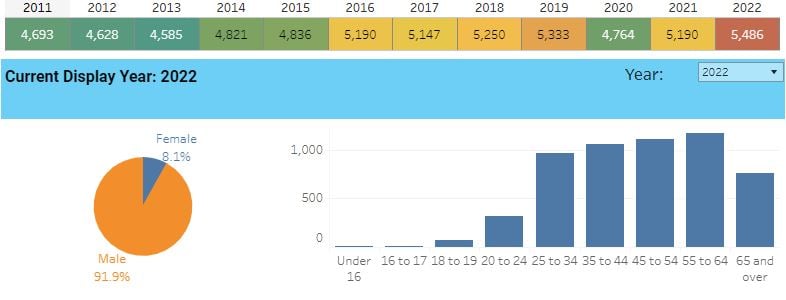

FACT #7: 2022 Was the Year With the Highest Work-Related Fatalities

In 2021, the transportation and warehousing industry saw the highest number of reported fatalities, totaling 1,053 fatal injuries, which accounted for 19% of fatalities across all industries.

While the overall number of 1,053 workplace fatalities may not appear high when considering the sector employs millions of workers, it takes on a different perspective when you think that 55 of these individuals were under the age of 25.

Figure 8: Fatal occupational injuries for the Transportation and Warehousing industry in the USA, 2011–2022.

Figure 9: Fatal occupational injuries for all industries in the USA, 2011–2022.

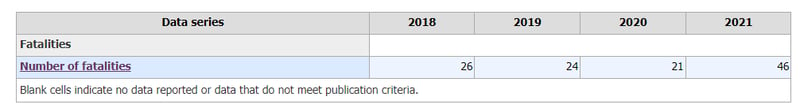

The data isn’t more encouraging when focusing on the warehousing and storage sector. The number of workplace fatalities per 100 full-time workers has more than doubled since 2020. These warehouse industry statistics underscore the significance of maintaining and enhancing safety practices in warehouse operations, highlighting the need for continuous safety awareness and improvement in this sector.

Figure 10: Number of workplace fatalities per 100 full-time workers in warehousing and storage.

FACT #8: Drone Usage Should Rise by 6% By 2025

A significant 82% of warehouses have recently invested in technology. By 2025, drone usage in warehouses is anticipated to rise by 6%, marking a shift towards automation, efficiency, sustainability, and adaptability. Predictions suggest that by 2030, autonomous vehicles and drones will handle 40% of global parcel deliveries [3].

Drones are set to improve efficiency and precision, generating substantial cost savings in labor and time. Workers can scan around 400 labels in an hour, whereas drones can process 1,500 labels per hour [4]. They also have the potential to reduce carbon emissions, boosting the environmental responsibility of warehousing companies.

Additionally, drones contribute to workplace safety by reducing the need for employees to perform hazardous tasks, particularly in warehouses with towering heights of up to 144 feet. They replace physical access to dangerous areas, such as climbing ladders, scaffolding, or elevated platforms, with efficient inspections and surveys conducted by drones.

FACT #9: Pickers Walk an Annual Distance Equivalent to the Moon

Pickers, also called order pickers, material handlers, picking associates, or warehouse operatives, are primarily responsible for finding and gathering products within the warehouse to meet customer orders.

Depending on the warehouse’s size, they may cover up to 10 or 12 miles per shift, translating to approximately 22,000 steps or 2,400 miles a year [5]! That’s more than the driving distance from Beverly Hills to Santa Monica!

A warehouse with approximately 100 employees adds up to over 240,000 miles covered by workers walking from aisle to aisle in a year—a distance equivalent to traveling from Earth to the moon!

FACT #10: Automation Can Increase Efficiency by 30% in Warehouses

Warehouse automation has seen a significant increase in recent years. As of 2020, approximately 4,000 automated warehouse units were installed worldwide, representing a 57% increase compared to the previous year.

The global warehouse automation market has experienced significant growth, increasing from $17.32 billion in 2022 to $19.78 billion in 2023 [6]. This growth highlights the substantial changes occurring in this sector and the increasing significance of automation technologies like robotics, AI, machine learning, and IoT, which enhance the efficiency and accuracy of warehouse operations.

This trend also indicates a rising interest in achieving operational excellence, which has the potential to redefine industry standards. Automation can boost production efficiency by 30% [7]. While significant focus has been on concerns about job loss due to automation, the reality is quite the opposite. Automation can generate new job opportunities, encourage skill development, and shift the employees’ roles to managing robots on the production line. Since nearly 45% of repetitive tasks can be automated, this transition can result in higher-paying and more fulfilling worker roles.

FACT #11: Warehouse Rack Innovations in Seismic Technologies

Rack engineering has seen remarkable innovations that focus on enhancing the safety and resilience of storage systems. From advancements in materials to cutting-edge design concepts, these innovations aim to optimize storage solutions and improve overall rack functionality.

One remarkable advancement is the integration of seismic racks designed to withstand the forces of earthquakes and other seismic events. These racks use special engineering techniques, such as flexible connections and bracing, to absorb and dissipate seismic energy, preventing catastrophic failures and protecting valuable inventory.

Another groundbreaking technology gaining attention is base isolation technology. Placing this technology between the columns of upright frames and anchoring it to the floor can mitigate the effects of seismic forces on the rack structure. Some systems enable the rack’s upright frames to move during a seismic event, dissipating up to 85% of the seismic energy and withstanding earthquakes with an intensity 25% greater than those reaching magnitudes of 6.7 and 6.9 on the Richter scale [8].

Conclusion: The Future of Warehousing

In the warehousing world, there’s more than meets the eye: it is a realm of endless possibilities. With warehouse trends moving towards automation, workplace safety, and innovative solutions, the future of this industry promises to be as intriguing as the fascinating facts we’ve explored.

These facts may surprise you, but they all have one thing in common: they underline the critical importance of warehouse efficiency and safety.

SOME FUN WORLD RECORDS RELATED TO WAREHOUSING

WORLD RECORD #1: Longest Forklift Pallet Relay

In 2018, the USA established a record for the longest forklift pallet relay. This achievement involved a team of six drivers who completed 126 consecutive passes in the relay [9].

WORLD RECORD #2: Most People Wearing High-Visibility Vests and Hard Hats

In 2019, in Australia, a record was set for the most people wearing high-visibility vests, with 2,499 participants [10].

The same year, a record was established in the USA for the most significant assembly of individuals wearing hard hats, involving 2,136 participants [11].

These accomplishments underscore the importance of employee safety.

WORLD RECORD #3: Longest Line of Pallets

In Hong Kong, in 2017, the longest line of pallets was created, extending over 3,348 feet. To accomplish this, 8,000 Loscam pallets were arranged to form an enormous 54,000-foot maze designed in the shape of “HK” [12].

WORLD RECORD #4: Largest Storage Facility for Aircraft

In Arizona, the Aerospace Maintenance and Regeneration Center (AMARC) provides storage on a vast 2,600-acre area for 4,200 aircraft, 40 aerospace vehicles, and an extensive inventory of 350,000 production tooling line items [13].

WORLD RECORD #5: Warehouse Filled with Record-Breaking One Piece Collection

A Hong Kong man holds the World Record for owning the most One Piece memorabilia, with 20,125 items. He estimates he spent over 500,000 yuan ($73,700) on this collection. These items are kept in a 1,000-square-foot warehouse, which also serves as a museum and a meeting place for One Piece cosplayers [14].

Sources:

[1] https://www.wsj.com/articles/warehouse-giant-prologis-to-offer-more-peripheral-services-cfo-says-11643193003

[2] https://www.kokeinc.com/blog/warehouse/shocking-safety-warehouse-statistics/

[3] https://zipdo.co/statistics/warehousing-industry/

[4] https://www.designworldonline.com/drones-take-the-night-shift-for-improved-inventory-tracking/

[5] https://goclove.com/blogs/news/10-jobs-that-commonly-exceed-10-000-steps-per-day

[6] https://www.globenewswire.com/news-release/2023/09/11/2740612/28124/en/Warehouse-Automation-Global-Market-Report-2023-Innovation-Thrives-in-Warehouse-Automation-R-D-Focus-Shapes-Future-of-Operational-Efficiency.html

[7] https://www.innovativeautomation.com/automation-systems-drive-efficiency-quality/

[8] https://www.ridgurak.com/accessories-options/frame-options/the-pellegrino-seismic-base-isolation-system/

[9] https://www.guinnessworldrecords.com/world-records/400144-longest-forklift-pallet-relay

[10] https://www.guinnessworldrecords.com/world-records/101089-most-people-wearing-high-visibility-vests

[11] https://www.guinnessworldrecords.com/world-records/99827-largest-gathering-of-people-wearing-hard-hats

[12] https://www.loscam.com/en/media/press-release/11

[13] http://www.amarcexperience.com/ui/index.php?option=com_content&view=article&id=2&Itemid=213

[14] https://www.guinnessworldrecords.com/news/2023/1/one-piece-superfan-fills-warehouse-with-record-breaking-collection-735203

Figure 1: https://www.stoecklin.com/en/references/das-neue-hochregallager-der-ems-chemie-ag-projekt-sprint-in-marathondistanz

Figure 2: https://www.mecalux.com/case-studies/automated-clad-rack-warehouse-hayat#Pictures-1

Figure 3: https://science.howstuffworks.com/transport/flight/modern/boeings-everett-facility-is-largest-building-on-earth.htm

Figure 4: https://www.wsj.com/articles/warehouse-giant-prologis-to-offer-more-peripheral-services-cfo-says-11643193003

Figures 6, 7, 8 & 9: https://injuryfacts.nsc.org/work/industry-incidence-rates/industry-profiles/