Chemical warehouses are some of the highest-risk storage environments in North America. A single oversight, like mislabeling a flammable liquid or storing incompatible substances side by side, can result in fire, toxic exposure, or a rack collapse that ruptures hazardous containers.

In this guide, you’ll learn how to protect your warehouse by designing and maintaining racking systems that meet OSHA, NFPA, and ANSI standards, backed by engineering insights from Damotech, North America’s pallet rack safety leader.

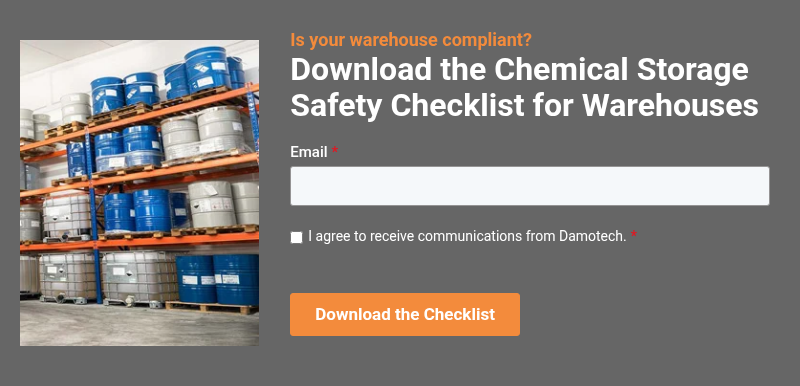

Download our Chemical Warehouse Safety Checklist to assess your facility’s compliance.

Chemical warehouse aisle with secure pallet racking, IBC containers, and blue drums—demonstrating compliant storage practices and impact-protected uprights. Photo Credit: DEF Warehouse

Why Chemical Warehousing Demands Higher Safety Standards

Unlike general-purpose warehousing, chemical storage facilities face layered threats:

- Fire & explosion: Flammable vapors can ignite with a single spark.

- Structural overload: Heavy drums and totes create strain on racks not engineered for chemical loads.

- Corrosion: Vapors and spills degrade metal, compromising racking faster than in typical environments.

- Regulatory pressure: Every year, thousands of companies are fined for unsafe chemical storage. OSHA penalties can reach $16,500 for each serious violation and up to $165,514 for repeated or willful violations.

A real-world reminder came in 2023 when a warehouse in Euclid, Ohio, caught fire. First responders discovered large quantities of magnesium, an explosive metal that reacts violently with water. Fortunately, it was contained in a sealed oven. Without that precaution, the result could have been catastrophic.

Proper rack protection, regular inspections, and engineering oversight aren’t optional—they’re essential infrastructure for chemical warehouse safety.

Understanding Hazmat Warehousing

Hazmat warehousing refers to the storage of materials regulated as hazardous by agencies like:

- OSHA – Focuses on human safety and workplace exposure

- EPA – Regulates environmental risks

- DOT – Manages labeling and transport of dangerous goods

Substances deemed hazardous can include:

- Carcinogens

- Irritants or corrosives

- Flammable gases, liquids, and solids

- Oxidizers and reactive agents

Substances are categorized into hazard classes such as flammable, toxic, corrosive, and oxidizer, as defined by regulatory standards.

- Label and segregate chemicals properly

- Follow compatibility rules

- Use structurally sound racking

- Train workers on emergency response

Chemical racking systems must be engineered to support the physical load and the hazard class of their contents.

Employees must be trained not just to store these chemicals properly, but to respond when things go wrong. That means safe racking configurations, physical barriers, engineered inspections, and safety data visibility must all work in sync.

Common Chemical Hazards in Warehouses

| Hazard Type | Examples | Risk to Racking |

|---|---|---|

| Flammables | Acetone, methanol, gasoline | Fire/explosion on impact |

| Corrosives | Nitric acid, sodium hydroxide | Accelerated steel corrosion |

| Toxics | Hydrogen sulfide, formaldehyde | Airborne exposure, PPE required |

| Reactive substances | Sodium metal, lithium | Violent reactions with air/water |

| Compressed gases | Chlorine, oxygen, CO | Rupture, projectile risks |

In a chemical environment, a minor rack failure can spill thousands of liters of volatile liquids, turning a mechanical issue into a life-threatening event. That’s why chemical warehouse racking must go beyond the basics.

What OSHA and NFPA Say About Chemical Storage

OSHA 1910.106 – Flammable Liquids

- Segregation by class (I–III)

- Containers must be fire-rated

- Eyewash stations, spill controls required

- Racks must support secondary containment loads

NFPA 30 – Flammable and Combustible Liquids Code

- Requires specific aisle widths

- Defines rack clearance (e.g., all stored items must be kept at least 36 inches from overhead beams)

- Requires proper sprinkler coverage above racks

ANSI MH16.1 – Steel Storage Racks

- All racking must display load plaques

- Any change in beam height, rack type, or material must be re-evaluated by an engineer

- Corroded uprights or degraded anchors require immediate repair or replacement

Need help understanding which standards apply to your facility? Talk to a Damotech expert.

Rack Safety Risks Unique to Chemical Warehousing

- Undetected corrosion: Fumes or spills degrade structural integrity

- Overloading: Chemicals in drums or totes can exceed rack limits

- Label damage: Obscured load plaques cause misuse

- Reconfiguration without engineering approval: Voids compliance and liability protection

Chemical Storage Best Practices for Racks

1. Use Resistant Materials

Galvanized steel offers effective protection in corrosive environments.

2. Reinforce Anchoring

Chemical zones often require seismic-grade anchoring due to potential explosive risk or drum movement.

3. Implement Spill Containment

Secondary containment systems must be sized based on total volume and rack location.

4. Maintain Proper Clearances

Ensure racking is installed away from HVAC vents, fire doors, or incompatible chemical zones.

How to Store and Segregate Chemicals

Storing chemicals isn’t just about containers—it’s about compatibility.

| Category | Keep Separate From | Examples |

|---|---|---|

| Flammables | Oxidizers, corrosives | Acetone, ethanol |

| Oxidizers | Flammables, reducers | Bleach, ammonium nitrate |

| Acids | Bases, oxidizers | Sulfuric, nitric, acetic acid |

| Bases | Acids, flammable organics | Sodium hydroxide, ammonia |

| Compressed Gases | Heat sources, flammable gases | Chlorine, carbon monoxide |

Why Racking Inspections Are Non-Negotiable

Chemical exposure degrades metal faster than in standard environments. Without regular inspections, you risk silent failures—bent beams, rusted anchors, out-of-plumb uprights. These failures compound when paired with heavy drums or totes.

Damotech offers engineer-led inspections of racking systems in chemical environments, meeting ANSI, OSHA, and CSA standards.

What Is a Safety Data Sheet (SDS) and Why Does It Matter

Every chemical must have an SDS on file and easily accessible. This document contains vital data on handling, storage, PPE, and emergency response.

💡 If your racking configuration doesn’t match the handling and segregation guidance on your SDS, you’re out of compliance.

Conducting a chemical hazard assessment with NFPA labeling and SDS data—critical for safe storage, handling, and regulatory compliance in chemical warehouses. Photo Credit: American Hazmat Rentals

Personal Protective Equipment (PPE) for Chemical Warehousing

| Type | Protection for |

|---|---|

| Chemical gloves | Hands (burns, irritation) |

| Splash goggles | Eyes (corrosives, vapors) |

| SCBAs | Inhalation hazards |

| Steel-toed boots | Dropped containers |

| Full-body suits | High-risk spill areas |

Warehouse workers wearing full PPE and hazmat suits safely handling chemical drums with a pallet jack, demonstrating proper spill response and OSHA-compliant chemical storage procedures. Photo Credit: Grainger

Download our free Warehouse Worker Safety Guide for more information on how to protect your employees in high-risk environments.

How Damotech Supports Chemical Warehouse Safety

- Engineer-led rack inspections with digital reports

- Lifetime-guaranteed repair kits with resistant finishes

- Software to track rack condition and maintenance tasks

- Training services for employees and EH&S teams

Over 50% of Fortune 500 companies rely on Damotech for rack safety. Your chemical warehouse should too.

Final Word: Safety Starts with Structure

Chemical warehouse safety isn’t optional—it’s structural. From choosing the right rack system to enforcing segregation and scheduling regular inspections, every decision either reduces or multiplies risk.

The Euclid fire reminded us how quickly things can escalate. But it also proved one thing: when systems are engineered for safety, disaster can be prevented.

Book your engineer-led rack inspection now. Protect your people. Safeguard your inventory. Comply with confidence.

Do you have damaged racks in your warehouse? Our experienced rack experts will come to your facility to assess the damage at no cost and with no obligation. Book a free on-site pallet rack repair assessment.

FAQ About Chemical Warehouses

How do I know if my warehouse racking is safe for storing chemicals?

Your racking is safe for chemical storage if it’s corrosion-resistant, structurally sound, properly anchored, and compliant with ANSI MH16.1 and OSHA 1910.106. You should also have clear load plaques, compatible chemical segregation, and documentation of regular inspections by qualified professionals. Any visible corrosion, missing labels, or unverified modifications are red flags that require immediate engineering review.

Do I need special racking to store flammable or corrosive chemicals?

Yes. Flammable and corrosive chemicals can accelerate metal degradation or trigger dangerous reactions during a rack failure. Your racking should use corrosion-resistant materials (galvanized or powder-coated steel), be professionally anchored, and be designed to support the specific loads and compatibility zones required for chemical storage.

How often should chemical warehouse racking be inspected?

Chemical warehouse racking should be inspected at least annually, or more frequently if exposed to corrosive materials, impacts, or spills. ANSI MH16.1 and CSA A344.1 recommend that inspections be conducted by trained professionals, ideally engineers familiar with chemical environments. In-house monthly visual checks are also recommended.

What is chemical segregation in a warehouse?

Chemical segregation is the practice of storing incompatible substances apart to prevent dangerous reactions. Common rules include separating acids from bases, oxidizers from flammables, and water-reactive chemicals from moisture-prone zones. Proper segregation reduces fire and explosion risks and is mandated by OSHA, NFPA 30, and SDS guidance. Take a look at the segregation chart to ensure your warehouse follows proper chemical compatibility groupings.

What should I do after a chemical spill in a warehouse?

Even with the best precautions, spills can happen. After a chemical spill, follow these general steps:

- Identify what was spilled, where, and why. This determines how to clean up safely and what caused the failure, such as damaged racking.

- Liquids can splash onto racking, lift forks, and nearby product. Always check for contamination that could lead to slips, corrosion, or rack instability.

- Ensure clean-up stations are stocked with proper absorbents, signage, and PPE. SDS sheets must be accessible to guide safe handling.

- Document the incident, update your training or inspection schedule, and make changes to prevent recurrence. In many cases, OSHA requires operators to be retrained or recertified following a spill or near-miss.

Do you have damaged racks in your warehouse? Book a free on-site pallet rack repair assessment »