How to use safety bars to prevent accidents in your warehouse

Having material fall from a pallet rack system can be a tragedy for anyone involved. Although pallet racks have cemented their position as one of the most efficient ways of storing material goods, if the proper safety precautions are not taken, they could be a source of material damage or even human injury. Therefore, it is important to take preventive measures to reduce the risk of having stored material fall onto lower beam levels, aisles below, or in the aisle. Luckily, many different racking components have been devised to prevent such occurrences. These include wire mesh decks, nets, screen panels, support bars, and safety bars.

This blog post focuses on pallet rack safety bars and presents some of the most important aspects of this safety device.

What is a safety bar’s purpose?

According to North American codes and standards, safety bars can be defined as follows:

“a member supported by and oriented perpendicular to load beams, intended to temporarily support misplaced pallets”.

Per this definition, the role of a safety bar in a racking system is to prevent the fall of pallets that are not adequately resting on the front and back beams. Note that the definition also states that safety bars are intended to temporarily support misplaced pallets, meaning that they should not be relied upon to consistently carry heavy loads, and any misplaced pallet should be quickly re-positioned upon discovery. In the event that a pallet cannot rest directly on both beams due to size, strength, or style restrictions, pallet support bars can be installed instead. These members are positioned in a similar fashion to safety bars but are designed to actually support the full weight of the pallet.

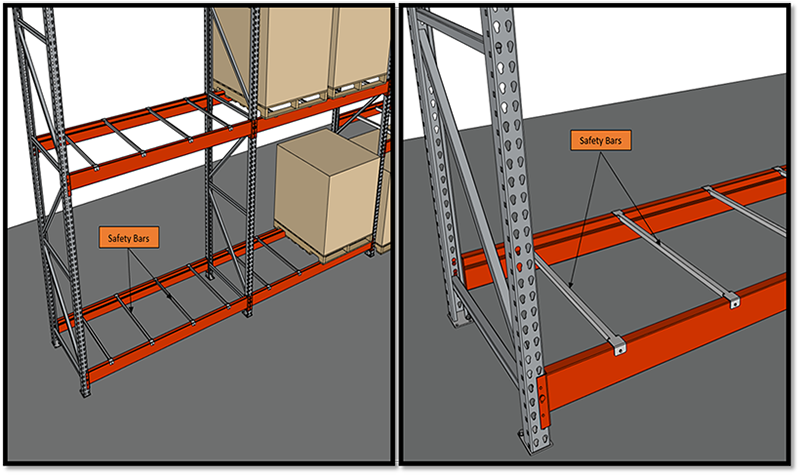

Figure 1: A representation of safety bars within a pallet rack system

Figure 1: A representation of safety bars within a pallet rack systemDoes every beam level need safety bars installed?

North American codes and standards state that although safety bars are not mandatory, they are highly recommended. There are some exceptions to this, however. As an example, for beam levels directly above a tunnel or door, where the presence of pedestrians or forklift drivers is more likely, it is necessary to take additional measures to reduce the risk of falling objects. These measures often include the addition of wire mesh decking, which can come with safety bars already integrated within them. Nonetheless, in general, safety bars are an optional add-on to further increase the safety of a pallet rack system.

We can obtain confirmation of this by referring to the rack safety codes and standards published.

The Canadian Standards Association (CSA) has addressed this in their user guide for steel storage racks (A344-17):

5.3.5.2 (a)

Optional safety accessories can include the following items:

a) the addition of pallet safety bars or wire mesh decks placed between beams to reduce the risk of misplaced pallets from falling between supports

In this excerpt, safety bars are treated as optional safety accessories, yet their effectiveness in reducing the risk of falling pallets is acknowledged nonetheless.

If we then turn to the American National Standards Institute (ANSI) standards, we can pull from MH16.1; the rack design code specified in the IBC – (International Building Code) which is applied in the United States:

8.4.5 Product Fall Protection:

The owner should specify to the designer any locations where operations may require horizontal or vertical safety barriers. These barriers shall prevent products from falling into those areas.

In this case, a broader statement is given where it is essentially up to the owner to recognize potential risks of falling objects and to take preventive measures. Safety bars could be an appropriate preventive measure since, as mentioned earlier, they act as barriers that help prevent products from falling between beams.

How do you properly install safety bars?

Safety bars should be installed between the front and back beam of the same beam level. They should also be placed perpendicular to the beams. Another requirement is that they be attached to both beams to prevent any lateral displacement. To achieve this, safety bars are most often screwed directly into the beams or clipped into them if they are compatible and designed to do so. Failure to properly attach safety bars is a recurring issue found during Damotech conformity inspections.

The reason such measures are required is to prevent the safety bars from being dislodged and moved out of position. This can create larger areas of free space beneath a pallet, which might make it more susceptible to falling through. Furthermore, the safety bars themselves can become potential falling objects. The CSA also states that during a rack inspection, safety bars that are not positively restrained against lateral displacement should be identified. The image below shows an example of this. From the scratched paint on the beam, we can get a sense of how often the safety bars slide along it.

Lastly, it is necessary to have at least 2 safety bars per pallet position. Therefore, if a beam level was designed to support 2 pallets, 4 safety bars are required on the pair of beams. Damotech recommends placing safety bars at ¼ and ¾ of a pallet’s width.

This picture shows an example of safety bars that are not properly attached to a beam.

This picture shows an example of safety bars that are not properly attached to a beam.

In this second picture, a pallet has fallen between its supporting beams. Safety bars could have prevented this kind of incident from happening.

Recommendations

Safety bars undeniably help to reduce the risk of having stored material fall from pallet rack systems. This applies of course if the safety bars are installed correctly. Rack owners should always ensure that their safety bars are properly secured and compatible with the beams being used.

To learn about more ways to improve rack safety, this article goes over 5 strategies that will help reduce the chances of accidents!

-

References

Canadian Standards Association. (2017). User guide for steel storage racks (A344-17).

American National Standards Institute. (2012). Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks (MH16.1-2012).

Commission on workplace standards, fairness, health, and safety. (2005). Prevention Guide: Safety of Pallet Racks – Construction, purchase, installation, and use (CNESST).