When it comes to protecting our buildings from vehicle collisions, the first thing that comes to mind is shielding the main structural elements like the columns, the walls, the beams, and even the stairs. When impacted and damaged by vehicular activity, building columns can pose serious risks, given the role they play in the stability of the structure. Because it affects the construction’s integrity, addressing damage to building columns is difficult and costly.

To prevent expensive and disrupting repairs, column protectors are a smart investment. There are different protection devices available on the market and choosing the correct one for your specific building environment may seem like a daunting task.

Fork puncture through a steel tube building column and… a very bad day at the office!

This blog goes over some of the more common types of protection to help you choose the best option for your needs. More specifically, we compare 2 types of column protectors mostly made of steel and/or plastic and evaluate their durability and efficiency.

|

Two types of products are more commonly seen to protect building columns in various environments such as garages, indoor parking areas, warehouses, and distribution centers. Before we dig deeper into the comparison, let’s go over the two types of column protectors analyzed in this blog post:

1. Dedicated column protectors

Those protectors surround the building column like a fence and are sometimes called “round column guards” or “column bumpers”. They typically surround the column continuously on all sides. The plastic ones wrap around the column and act like a car bumper – if you hit the bumper, the car will feel the impact. Steel dedicated column protectors like the DAMO SHIELD are NOT in contact with the column. Because they are bolted directly into the floor, when they are hit, the column remains untouched.

Photo credits: brandsafeprotection.com

2. Bollards

Bollards are typically anchored to the ground. These safety devices can be used for a wide variety of applications and protecting building columns is one of them. They also vary significantly in material, design, and installation.

Photo credits: brandsafeprotection.com

To help you choose the best option, let’s now jump into the comparison. We will analyze durability and efficiency for every type of column protector, dedicated, and bollards.

|

Dedicated column protectors

Steel

Let’s explore steel dedicated column protectors first. One example of this type of protection is the DAMO SHIELD. This protector surrounds the building column and is anchored to the concrete floor. Because the protector remains independent, the impacts it receives are not transferred to the building column.

Made of ¼” thick structural steel, it can withstand repeated and significant collisions. Another metric to analyze is the warranty provided by the manufacturer. A longer warranty can be a good indication of a manufacturer’s trust in the durability of their product, while also leaving you with peace of mind.

The DAMO SHIELD, for example, comes with a 10-year manufacturer’s warranty. This means that the absence of material and workmanship defects is guaranteed for that period. As we will see, this is much longer than the common warranties available for the other types of protection.

Plastic

Plastic column surrounding protectors are like steel protectors in shape. However, the fact that they are made of plastic instead of steel tends to reduce their durability. For example, they are much more susceptible to being punctured by the forks of a forklift. If we turn to warranties, we find that it widely varies between manufacturers, but a 90-day or less warranty is not uncommon, which pales in comparison to the 10-year warranty previously mentioned.

Bollards

Steel

Generally, bollards that are fixed are more durable than retractable ones. For protective purposes, it is ideal to have bollards made of steel with embedded concrete, as they offer higher durability than other types of bollards. Just like the steel dedicated column protectors, they are independent of the structure they protect. Warranties also vary greatly for different types of bollards, but a 1 to 5-year warranty is common. Additionally, unlike most dedicated column protectors, bollards do not provide wrap-around protection, leaving sections of unprotected areas around the building column.

Plastic

Plastic bollards are mostly used for their flexible quality. In many cases, they are meant to give indications regarding the circulation in specific areas, like controlling access to a section of a park, warehouse, or street, for example. They are easy to use, relatively inexpensive, often removable, and reusable, which makes them a good and durable option in some situations.

|

|

DEDICATED COLUMN PROTECTORS |

|

|

Pros |

Cons |

|

|

|

BOLLARDS |

|

|

Pros |

Cons |

|

|

|

Dedicated column protectors

Steel

When it comes to how efficient a steel column surrounding protector is, it really depends on the manufacturer. If we take the DAMO SHIELD as an example once again, its efficiency relies on strategic key elements, like the fact that it is anchored directly into the ground. This characteristic makes it especially efficient since it is completely independent of the column. Therefore, the column remains untouched when the DAMO SHIELD is hit.

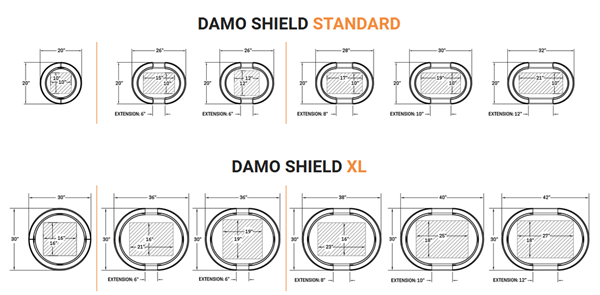

A variety of standard sizes are available to fit around the most common structures. The protector can also be customized to take other shapes, for optimized protection. This could be useful if the building structure also houses other equipment such as pipes or fire extinguishers that need to be accessible. Steel extensions are also available if needed.

Regardless of their shape, the fact that they usually surround the column continuously on all sides makes them an efficient option, since they protect most of the area of the column. Another factor to consider is the ease of installation. The installation of a DAMO SHIELD can be completed in under 30 minutes, without disrupting warehouse operations.

Plastic

Plastic protectors also come in a variety of different shapes and sizes to fit around most standard building columns. These protectors don’t usually offer customization options and don’t often deviate from the standard available sizes. However, some can securely cover a range of sizes, accommodating varying building column dimensions.

In terms of impact protection, plastic protectors commonly wrap around the column and rely on them for support: they are not anchored to the ground. Because of this, impacts are transferred to the structure supporting the protector, which can cause significant damage.

Positive aspects of plastic protectors are the ease of installation or removal and the prices. Since these devices are usually secured by bolts, clips, or straps, and aren’t typically anchored to the ground, the installation can be done in just a few minutes with minimal to no tools required. The same can be said about the removal process if things such as maintenance or cleaning need to be done to the building column. As for the prices, they tend to be less expensive than steel column protection, commonly ranging between $200 and $600.

Bollards

Steel

As for bollards, due to their relatively small size, they can be placed almost anywhere in a warehouse. They can also focus the protection on a single region of a building structure. For example, if a column only has 1 corner exposed to high forklift activity, installing a bollard could be a better solution than surrounding the entire column with protection. The type of bollard being installed also impacts its efficiency.

Embedding a bollard into concrete requires more time and effort than anchoring it to the ground – although it increases the bollard’s sturdiness. As you can imagine, the removal process could also vary. Either way, additional tools would be required for both processes. Also, because bollards are installed a few centimeters from the others, the gaps between the posts leave some areas of the columns unprotected.

Plastic

As previously mentioned, plastic bollards are mostly used in public settings, to control pedestrian circulation in specific areas. Since they are easy to use, relatively inexpensive, and often removable, they become an efficient option for situations where repeated impacts by vehicles are not involved.

|

|

DEDICATED COLUMN PROTECTORS |

|

|

Pros |

Cons |

|

|

|

BOLLARDS |

|

|

Pros |

Cons |

|

|

Recommendations

Once you realize the importance of protecting your building columns, useful information on the different options will help you reflect on your specific needs: you’ll then be able to make the best decision for your building.

Always keeping safety top of mind, many options are available to improve the current situation in your building. On top of building column protectors, other products such as the DAMO GUARDRAIL and the DAMO FENCE can be added to improve protection across your building.

Protecting the integrity of your building structures will help ensure smoother day-to-day operations. Ultimately, it will make it easier for you to keep your employees, your products, and your building safe!