In the world of cosmetics, where beauty products are delicate, compliance is strict, and consumer expectations are sky-high, the warehouse is more than a place of storage—it’s the heartbeat of logistics. Whether you’re managing limited-edition makeup drops, temperature-sensitive skincare, or high-turnover promotions, your rack infrastructure must be as precise and resilient as your brand reputation.

With the right racking strategies, health and beauty warehouses can enhance safety, efficiency, and sustainability.

Inside Beauty Pie’s cosmetic warehouse, high-density racking and efficient pick-pack operations support fast-paced health and beauty logistics. Photo Credit: GXO Logistics

7 Reasons Every Cosmetic Warehouse Needs Safer Racking

- Complex Logistics Demands Require Precision Infrastructure

Cosmetic warehouses manage high SKU volume, temperature-sensitive goods, and strict regulatory compliance—all of which increase rack system stress and complexity.

- The Cost of Rack Failure Is Too High to Ignore

Product loss, injuries, and operational downtime can result from a single rack failure, especially in fast-pick or automated zones.

- Recurring Risks in Cosmetic Fulfillment Need Targeted Solutions

From pallet overhang to forklift damage and humidity-induced corrosion, the beauty industry faces distinct safety challenges that demand proactive rack reinforcement.

- Leading Brands Already Invest in Safer, Smarter Racking

Case studies like Sephora and L’Oréal warehouses demonstrate how modern cosmetic logistics depend on optimized racking to scale fulfillment and maintain brand reputation.

- Damotech Engineering Services Ensure Compliance & Custom Fit

Certified inspections, load capacity labeling, and GMP-aligned layout design are critical for audit-readiness in regulated environments.

- Repair Kits and Protection Products Extend Rack Life Without Disruption

Damotech’s repair and protection systems allow cosmetic warehouses to stay operational while reducing long-term maintenance costs.

- Cloud-Based Rack Software Simplifies Multi-Site Safety Management

With tools like the Damotech Platform, warehouses can manage inspections, track deficiencies, and enforce corporate standards across locations.

What Makes Health & Beauty Logistics Unique?

From Sephora to L’Oréal, beauty brands demand warehousing that balances speed, precision, and compliance:

- SKU Proliferation: Dozens of shades, formulas, and packaging types increase storage complexity.

- Temperature & Humidity Sensitivity: Skincare, fragrances, and organic beauty products demand tight environmental control.

- Strict Regulatory Oversight: Facilities must comply with GMP, FDA, and Health Canada standards.

- Promotional Surges: Product drops and seasonal campaigns cause sharp inventory peaks.

- Fragility & Spill Risk: Glass packaging, flammable materials, and liquids pose safety and handling risks.

- Sustainability Pressure: More brands are embracing biodegradable packaging and low-emission distribution models.

These demands intensify pressure on pallet racking systems to perform flawlessly, with zero margin for safety lapses.

A state-of-the-art L’Oréal distribution center equipped with high-density racking and automated conveyor systems, demonstrating the infrastructure demands of modern cosmetic logistics. Photo Credit: beautytmr.com

The Cost of Rack Failure in Beauty Warehouses

Cosmetic logistics is high stakes. A single rack failure can cause:

- Product loss from spills, breakage, or contamination

- Operational downtime, sometimes halting entire order fulfillment flows

- Compliance violations, risking fines or audit failure

- Injury and liability risks from falling products or collapsed systems

When you’re managing thousands of lightweight, high-value SKUs, even small damage can cause major disruptions. This is especially critical in fast-pick areas or automated environments, where damaged racks can interfere with robotic systems.

Top Rack Safety Risks in Cosmetic Distribution

Cosmetic warehouses face specific rack safety challenges:

1. Pallet Overhang & Lightweight Loads

Odd-shaped packaging leads to improper pallet placement, increasing the risk of falls or rack imbalance.

2. Frequent Forklift Traffic in Pick Zones

High-turn inventory in e-comm lanes results in repetitive low-level rack impacts and damage.

3. Environmental Degradation

Beauty warehouses with high humidity or cleaning chemical exposure risk faster rack corrosion.

4. Improvised Configurations

Temporary expansions or floor plan changes often overlook engineering sign-off, putting structural integrity at risk.

5. Visual Obstruction from Branding Materials

Larger POS displays or packaging inserts may conceal damage or loosened components.

Case in Point: L’Oréal & Sephora Logistics

L’Oréal’s expanded Montreal distribution center exemplifies how automation and sustainable design come together. It features:

- High-density storage zones for e-commerce

- Extra 20,000 pallets of storage capacity on a 95,000-square-foot area, which represents a storage density 57% higher than previously

- 100% renewable energy

Similarly, with over 3,200 points of sale in 35 markets, Sephora must scale rapidly for global launches and influencer promotions. Sephora distribution centres’ success hinges on:

- Automated warehouse systems (e.g., WMS, robotic picking)

- Environmental controls for cosmetics stability

- Lean inventory flows to avoid product expiration

- Peak season throughput for gift sets and seasonal collections

Proactive rack inspections and repair protocols are essential in such high-volume environments. Even minor upright damage can bottleneck operations during peak demand.

A Sephora team member surveys high-density pallet racking in a cosmetic warehouse, highlighting the importance of rack safety in fast-paced beauty logistics. Photo Credit: greatplacetowork.com

How Damotech Supports Health & Beauty Warehouses

Damotech’s complete suite of solutions is tailored to help cosmetic logistics operations protect uptime and maintain compliance:

Engineering Services

- Load capacity certifications and plaques (LARCs)

- Annual rack compliance inspections (required in many jurisdictions)

- Customized layout analysis for GMP-compliant designs

Want to ensure your racking is GMP- and audit-compliant? Explore our Engineering Services to learn more.

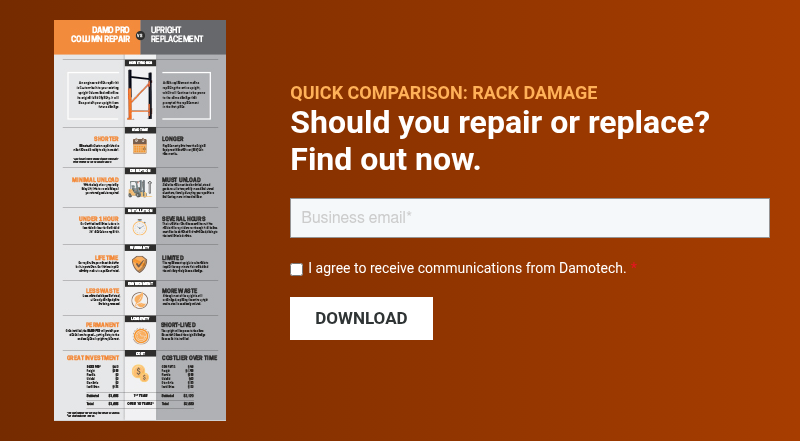

Rack Repair Kits

- Eliminate the need for full rack replacement

- Installable with minimal inventory disturbance (ideal for climate-controlled environments)

- Lifetime impact warranty (for Damo Pro repair kit)

Avoid costly rack replacements with our impact-resistant rack repair kits designed for warehouse environments.

Rack and Warehouse Protection Units

- Guardrails, end-of-aisle posts, and upright protectors

- Ideal for high-traffic pick-pack zones

- Prevent recurring damage

Protect your high-traffic fulfillment zones with our rack protection products.

Inspection & Maintenance Software

- Cloud-based safety dashboard

- Track multiple warehouses, schedule visits, archive inspection history

- Perfect for distributed cosmetic fulfillment networks

Manage rack safety across all your warehouses with the Damotech Platform.

Racking Compliance and Audit Readiness

Whether for an internal quality audit or an external GMP/FDA review, your rack systems must:

- Match certified load capacity labels/plaques

- Show no signs of unauthorized modifications

- Have inspection records on hand

Want to master rack safety like a pro? Watch our free video, Pallet Rack Inspections: Everything You Need to Know, led by Damotech’s chief engineer. It covers inspection types, recommended frequencies, compliance strategies, and free tools to help you maintain audit-ready warehouse racking.

Sustainability, Safety & Compliance: A Unified Strategy

Leading brands like L’Oréal are redesigning cosmetic warehouses to support:

- Sustainable packaging and reduced material waste

- Energy-efficient automation

- Eco-friendly transportation (e.g., EV fleets)

But sustainable logistics require durable, safe infrastructure. Corroded racks, inefficient layouts, and unreported damage all risk product integrity and regulatory violations.

Damotech ensures your warehouse racking systems evolve in tandem with your sustainability goals.

Build Safety Into Your Beauty Logistics Strategy

As e-commerce reshapes cosmetic supply chains, the warehouse has become a brand differentiator. Customers expect faster fulfillment, regulators demand tighter compliance, and operators must deliver without compromise.

Damotech helps health and beauty brands stay inspection-ready, damage-free, and fulfillment-optimized.

Talk to a rack safety expert or download our Rack Safety Program Guide to start optimizing today.

FAQ About Beauty Logistics & Cosmetic Warehouses

What are common safety challenges in health and beauty warehouses and distribution centres?

Cosmetic warehouses face unique safety challenges due to the fragility and regulatory sensitivity of cosmetic products. Common risks include:

- Rack damage from high-frequency forklift traffic in pick zones.

- Product spills or leaks from fragile, flammable, or liquid packaging.

- Pallet overhang or misalignment, especially with odd-sized cosmetics SKUs.

- Improper storage conditions leading to temperature or humidity degradation.

- Lack of consistent rack inspections, risking undetected damage.

Proactive rack protection, engineering-certified inspections, and compliant layouts are essential for safe operations.

What safety standards apply to cosmetic warehouses?

Cosmetic warehouses must comply with several safety standards, including:

- GMP (Good Manufacturing Practice) – Ensures proper handling and hygiene of cosmetic goods.

- FDA regulations (USA) – Governs cosmetic product storage under CFR Title 21.

- Health Canada requirements – Includes climate control and contamination prevention for natural health products.

- OSHA – Covers racking stability, signage, and safe working conditions.

- RMI/ANSI MH16.1 & MH16.3 – Provide design and maintenance standards for pallet rack systems.

Damotech helps warehouses and distribution centres meet these standards through engineering inspections, rack capacity labeling, and repair compliance.

What are the 7 reasons why cosmetic warehouses need rack safety solutions?

Beauty and cosmetic warehouses face unique logistics challenges that make rack safety solutions essential. Here are the 7 key reasons:

- Complex Logistics: High SKU counts, fragile packaging, and temperature-sensitive goods demand precise rack design.

- High Risk of Downtime: A single rack failure can disrupt fulfillment, especially in fast-pick or automated zones.

- Recurring Damage: Forklift impacts, pallet overhang, and humidity accelerate wear on racking systems.

- Industry Leaders Set the Standard: Brands like Sephora and L’Oréal rely on optimized racking to scale operations safely.

- Regulatory Compliance: Meeting GMP, FDA, and Health Canada requirements requires certified rack infrastructure.

- Cost-Efficient Maintenance: Repair kits and protection products prevent expensive full-rack replacements.

- Multi-Site Oversight: Cloud-based tools help operators track inspections and maintain safety across all warehouse locations.

Damotech’s rack safety solutions address all of these factors, keeping cosmetic logistics operations safe, compliant, and efficient.

How do you prevent pallet rack damage in high-turn zones?

To prevent rack damage in high-traffic, fast-pick areas:

- Install upright protectors like DAMO GUARD to absorb forklift impact.

- Use end-of-aisle barriers to shield structural frames from repeated contact.

- Conduct frequent rack inspections to catch issues early.

- Reinforce rack bases with repair kits instead of replacing full systems.

- Design wide-enough aisles to accommodate busy picking operations safely.

A proactive safety culture and physical protection go hand in hand.

Can you repair racking without unloading the beauty products?

Yes, using Damotech’s certified rack repair kits and the DAMO Easy Lift system, many racking issues can be safely repaired without unloading the entire bay. Depending on the height and severity of damage:

- 24" repairs typically don’t require unloading in uprights under 20 feet tall.

- 96" repairs may need selective unloading above or around the damaged area.

All repairs are done by trained technicians following strict safety procedures, minimizing disruption while restoring rack integrity. Discover the cost savings and operational benefits of choosing rack repair kits instead of replacing entire uprights.